Man-made diamonds: how do they look, how do they get them and where are they used?

Diamonds are distinguished by a unique density of the structure, allowing the stone to withstand heavy loads and high temperatures. This property is used in space experiments and developments, in the manufacture of medical devices and precision clocks, in the nuclear industry. After cutting a beautiful mineral turns into a diamond, which is appreciated by jewelers. Modern technology allows you to create it in artificial conditions, reducing the price without losing quality.

Features

For active use on an industrial scale artificial diamonds have been produced since 1993. Their quality was so high that jewelers needed to conduct special tests to determine the authenticity of the stones. For the average consumer, the difference was not obvious at all, so many companies began to use crystals to create luxurious jewelry.

In modern laboratories, several types of this synthetic stone are grown: cerussites, fabulites, rhinestones, ferroelectrics, moissanites. The most beautiful and pure is considered to be cubic zirconium dioxide, which is called "cubic zirconia". It is used in many areas of the industry, complements the collections of fashion houses of Thomas Sabo and Pandora.

The main features of artificially grown diamonds:

- low cost in comparison with natural stones (the price is 10-15 times less);

- ease of cut;

- no hidden defects that affect the hardness (air bubbles, cracks);

- full imitation of the real diamond after the cut.

Among the lovers of beautiful stones, opinions on the properties of non-natural stone were also divided. Some of them believe that only a true diamond is able to drive away evil spirits, protect its owner from damage and the evil eye, and helps him in commercial affairs.

Holders of artificial diamonds claim that their jewelry radiates positive energy no less effectively and brings good luck.

In recent years, artificial stones have been developed by well-known brands Diamond Foundry, Helzberg s Diamond Shops and LifeGem. This business in the United States is considered the most profitable and promising, since the harm to the environment is minimal. In addition, many geological experiments prove that the period of the formation of diamonds in nature is over. Therefore, the development of new deposits will soon become a thing of the past.

Receiving history

Real diamonds have been popular for several centuries. Costly diamonds decorated the royal clothes and crowns, were inherited and were included in the gold reserves of the treasury of many countries. Even today, cut minerals are the best investment, which only increases in price every year.

Therefore, the first development and attempts to create a synthetic stone began in the late XIX century.

The first artificial diamond was obtained in 1950 by Swedish scientists in the laboratory of ASEA. After researching their experience, the American firm General Electric repeated in 1956, having improved the technology. Over the course of several decades, new methods and developments have emerged that allowed the hue, shape and size of the synthetic mineral to change. In 1967, a patent was received for the cultivation of jewelry stones.

The history of their production in the Soviet Union begins with the first stone, which was synthesized at the Institute of Physics and High Pressure in the late 50s of the last century. But the active work in this direction is carried out by the scientist O. I. Leipunsky, who published many scientific papers and calculations back in 1946.

His work in the field of chemistry was used as the basis for new methods; they practically became the basis for modern industrial production of artificial diamonds.

The real breakthrough happened in the early 60s of the last century, when young scientists of the Moscow High Pressure Laboratory created a special press. With his help, it was possible to establish a large-scale production of heavy-duty stones: the volume reached a thousand carats per day. All manufactured technical diamonds were used for the needs of rocket production and mechanical engineering, were exported, bringing billions in profits.

In recent years, new technologies in Russia have been developed by private jewelry houses and scientific laboratories.

They attract foreign experts from South Africa, the United States and Europe, trying to make the method cheaper.

How are synthetic diamonds made?

Artificial diamonds grown in the laboratories of leading chemical companies are difficult to distinguish from real stone in terms of transparency and brilliance. But all known methods require large capital investments, are laborious.

Therefore, the main task of scientists is to find the perfect balance between quality and cost of production.

Methodology NRNT

HPHT or High Pressure, High Temperature is the most common technology. The basis of synthetic cubic zirconia scientists lay real stones the size of 0.5 mm. In a special chamber, on the principle of operation resembling an autoclave, a combination of a temperature of at least 1,400 ° C and a pressure of 55,000 atmospheres is created. Different chemical compounds, graphite layers, are superimposed on the natural base.

After 10 days of such exposure, strong sigma bonds appear, connections around the base are formed into a solid and transparent stone.

This technology recreates the natural conditions for the appearance of the mineral, so the quality is always at a height, defects are practically excluded.

CVD production or film synthesis

This technology is one of the first in the cultivation of artificial minerals. It is widely used when you need to create a very strong and sharp diamond coating, creating high-quality diamonds. All components and the diamond substrate are placed in special chambers that create a vacuum. After filling with methane, the exposure to microwave rays, well known for the operation of the microwave oven, begins. At high temperatures, chemical compounds of carbon begin to melt and combine with the base.

CVD technology gives high quality diamonds that are not inferior in their properties to the present. On their basis, the technology of replacing the wear-resistant boards of computers, dielectrics and ultra-thin scalpels in ophthalmology is being developed.

Scientists hope that in the near future for 1 carat of synthetic stones, obtained with the help of this technology, it will be possible to reduce the price to 5-8 dollars.

Explosive synthesis technique

One of the latest developments is the method of explosive synthesis. It is based on a combination of harsh heating of a chemical mixture by means of an explosion and subsequent freezing of the obtained mineral. The result is a synthetic diamond with natural properties, produced from crystalline carbon. But the high cost forces chemists to look for new variants of the synthesis of stone mass.

Scope of application

Among all diamonds, synthetic stones account for only 10% of the market. Cheap crystals of cubic zirconia are used for the manufacture of women's jewelry. The famous fashion houses decorate with them evening dresses, handbags and shoes, used in exclusive decor.

Progressive youth are increasingly choosing them for safety and environmental friendliness.

More than 90% of artificial diamonds are used in industry. Main directions:

- high-precision grinding machines, tools for cutting hard materials;

- microelectronics and computer manufacturing;

- defense industry;

- robotics;

- unique lasers for eye surgery;

- engineering;

- new machine tools in metallurgy;

- rocket science.

Among the latest achievements is the use of synthetic diamond for the manufacture of an artificial lens. Transplant operations have shown that the cleanliness and ease of cutting makes the implant ideal for the patient.

It is distinguished by the correct angle of refraction and durability.

Comparison with natural stones

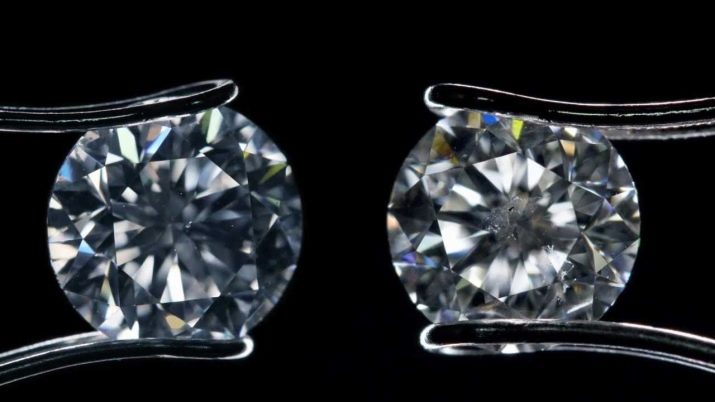

The industry produces synthetic diamond, so similar to a natural crystal that its identification requires a series of laboratory tests. Consider the most common differences.

- All artificially grown diamonds have a special stamp. It indicates the name of the company or laboratory that produced the product.

- For inspection it is better to use not a magnifying glass, but a powerful microscope. In the workshops, defects are detected using a spectrograph, shine through the rays of the ultraviolet.

- Real diamonds do not react to the electromagnetic field. As a verification method, you can use this property: a synthetic stone is attracted to a strong magnet.

- If you need to identify a diamond at home, it is put on white thick paper. On closer examination, growth zones that appear during the formation of a carbon layer under high pressure become noticeable.

- Natural stones are created from the smallest single crystals, therefore, have a uniform structure. Unnatural products, when examined in detail under a microscope, seem to be made up of a multitude of microscopic crystals.

Diamond exchanges around the world use special Diamond Check and M-Screen devices for analysis.

In just 10-15 seconds, they allow, with an accuracy of 95-98%, to distinguish synthetics from a natural stone, give maximum information about the quality and structure of the crystal.

The production of synthetic diamonds is described in the next video.