Clothes for professional training and sports are sewn from special materials.which possess a number of specific properties. What materials are used for this purpose - our article will tell.

Features

The material used for the production of a sports suit must meet the following requirements:

- High breathability. The suit should easily pass air so that the athlete is comfortable even during the most intense workouts. In addition, the fabric must pass moisture, not allowing to accumulate sweat under clothing.

- Strength. Tracksuit should be designed for a fairly serious load, stretch well and maintain its original shape.

- Practicality. The material should be easy to wash and dry quickly.

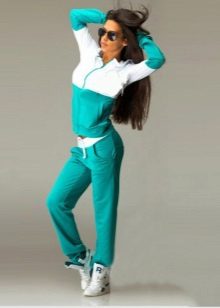

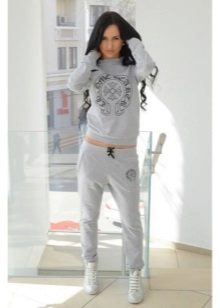

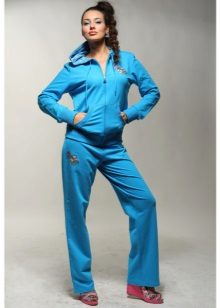

- Appearance attractive. It is good if the costume besides the basic functions also looks stylish and beautiful. In such clothes to do much nicer.

Kinds

To create sportswear are used, both natural and synthetic fabrics.

Cotton is one of the most popular and frequently used materials for tailoring sportswear. Among its advantages are: high strength, resistance to fading, excellent water and breathability, hypoallergenicity. Its disadvantages include relative fragility.

Canvas also has a cotton base. But, in contrast to the cotton suit, clothing from canvas is highly resistant to wear and maintains its original appearance for a long time. The material is very dense, does not stretch, practical in use.

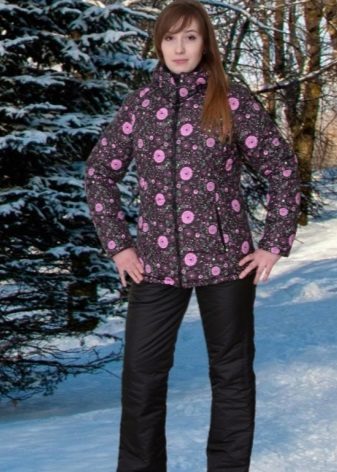

Wool is often used for sewing warmed models. It has goals with several advantages, including hygiene, high heat saving coefficient, hygroscopicity. By cons can be attributed, perhaps, only the difficulty in the care.

Silk is never used in its pure form, usually in combination with other materials. Adding silk fibers makes the material more durable, durable and attractive.

Footer - natural cotton material, very soft, pleasant to the touch, thanks to a special interlacing of threads. Sometimes used in combination with polyester yarns. The footer is divided into 2 groups: two-thread and three-thread.

Two-thread is formed by interlacing two threads. It is thinner, soft, lightweight, used with fleece lining. Three-thread - Bole dense and warm material that is suitable for use during the cold season.

The disadvantages of natural materials can be attributed to their unsuitability for sublimation, that is, to pass-through color. The decor and print are applied to them by means of embroidery on fabric, overhead details or silk-screen printing.

The advantages of synthetic materials, first of all, is their increased elasticity. Due to this, the service life of sportswear and the comfort of its use greatly increase. In addition, synthetic easy to maintain. It is very easy to wash, dries quickly, does not stretch and does not lose its shape. On the other hand, synthetics can cause an allergic reaction.

False mesh - synthetic material for tailoring sportswear. This is polyester, which has a very high wear resistance, practicality, ease of maintenance. The color does not fade and does not fade even after repeated washing. The material is very hygroscopic, and to improve its properties it is often treated with a special impregnation. The mesh is hypoallergenic, therefore it is applicable for making children's clothes.Most often material is used for tailoring a hockey, volleyball, football form. The mesh may have a different density.

Elastic externally it is an absolutely smooth material on the one hand and soft, warm, resembling a fleece, on the other. The material keeps warm well, so it is suitable for the autumn-spring period.

The main advantage of a duspo is a good windscreen. Of this material often sewn front, beautiful form. Sometimes the material is treated with a special impregnation. Clothing made from duspo is usually lined.

Micropolyester - a material based on polyester fibers. Possesses good density, durability, ease. It is almost not rumpled, well holds a form, is steady against burning out. The front side of the material has a soft, pleasant to the touch velvety surface.

The material Prince has a good water repellency, is easy to clean, durable, outwardly attractive.

Taslan - material based on polyamide. It is characterized by an unusual structure of weaving and the presence of a porous waterproof coating from the wrong side. The material is very light, durable, does not trap moisture, does not let down, is easy to use, resistant to friction, mechanical stretching and other loads.

Other materials include lycra, nylon, spandex, knitwear, antibacterial fabric, etc.

For tailoring a sports suit can be used several materials at once.with excellent physical and mechanical properties. As a rule, the outer part is made of waterproof polyester, warm fleece, lining mesh, etc. are used as the lining.

When buying a sports suit, you must carefully study the information on the composition of the fabric and how to care for it. Such information is placed on the label by the manufacturer. Careful and careful care is a guarantee of durability of any material.

Innovative technologies

Modern technologies are aimed at improving the materials not only for professional sports suits, but also for regular T-shirts, shorts, training pants and other clothes.

For example, Adidas pays special attention to the development of material that is as comfortable as possible for athletes involved in intense exercise. With active physical exercise, the body produces a large amount of sweat. The polyester microgrid used by the brand allows you to instantly absorb moisture and bring it to the surface with subsequent evaporation.

At the same time, the material also has an excellent breathable ability. Mesh material has a special tunnel design, so that the air is trapped in the cells, but it does not interfere with the absorption and sweat.

The athlete feels absolutely comfortable even with intense power loads.

Puma company is actively engaged in the implementation of innovative developments in its own production. The materials used perfectly absorb moisture. In addition, special anatomical inserts on clothing provide optimal thermo- and air regulation during training of different intensity. The capillary structure of the material allows you to retain heat and at the same time bring moisture to the surface.

Another innovative development from the company - PowerCELL. The principle of its work is based on the phenomenon of compression. Athletic tape, applied in special places under clothes, has a compression effect, micro-massage and improves the blood flow of the body. It is an ideal solution for long loads and workouts.

Nike is one of the world's leading manufacturers of sportswear. It is not surprising that this brand is also actively introducing the latest scientific developments into production. For example, for tailoring sports shorts, trousers and other clothing, the company uses recycled polyester microfiber.This material perfectly stretches in different directions, instantly absorbs sweat. It is perfectly washed and dries very quickly.

For lovers of natural fabrics microfiber is often used in combination with cotton. At the same time, the suit has all the advantages of synthetics, and its inner part, made of organic cotton, gives comfort and pleasant sensations during classes.