A cutting board is a must-have item in every kitchen. With its help processing and cutting of products is carried out, all culinary masterpieces are embodied in reality. Therefore, when choosing a board, one should pay attention to the quality characteristics of the product. A very popular stone cutting board is represented by a wide variety of shapes and colors, it is distinguished by a high level of wear resistance compared to plastic and wooden planks.

Kinds

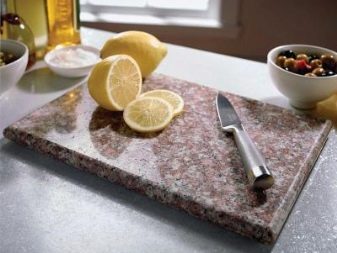

Most often stone chopping boards are a solid flat slab of marble or granite, as well as artificial stone.

Serving or finishing plates of granite and marble have high environmental performance, have bactericidal properties, since only natural materials without caustic impurities and dyes are used for their manufacture.

The surface of natural stone does not absorb foreign odors and does not allow the tastes of the products to mix, preserving their natural qualities.

High-strength cutting board made of artificial stone on the Italian technology from a natural mineral with addition of the painting components and pitches. Such products have a luxurious and sophisticated look, almost identical to natural stone boards. At the same time, an artificial variant of the cutting surface has a more affordable price and is distinguished by a long service life (over 15 years), besides, such accessories are suitable for all types of kitchen work.

The surfaces of acrylic material do not have pores and microcracks, in which bacteria and fungus can accumulate, for this reason, food products that are cut on such a board retain their beneficial properties.

Selection and operation rules

It is believed that for the kitchen of the average hostess requires at least 3 chopping plates to ensure the necessary level of hygiene and food safety. One should be for cutting bread and pastry, the second - for meat products, and the third - for vegetables and fruits. Each cook has the right to independently determine the necessary number of cutting boards, and they can be of various sizes and from different materials.

When operating cutting boards, it is necessary to take into account that for each product group there must be a separate surface. This is due to the fact that, for example, in raw fish and meat there can be various harmful microorganisms that, if they are applied to a product that is not subjected to heat treatment, can cause significant harm to health.

The main requirements that should be paid attention to when choosing a stone chopping board are: the quality of the material from which it is made. Natural or high-quality artificial stone should not have cracks, chips, traces of glue and foreign odors.

To date, there are many different models of cutting surfaces, differing in appearance, color, shape, size and scope.

In the world of modern technology and the development of culinary art, small-sized boards are used not only for cutting and slicing products, but are also an elegant decorative element for serving and serving dishes.

The black board looks very stylish when serving Japanese and Mediterranean dishes.As well as granite or serving marble surface complement the interior of a modern cafeteria or fusion restaurant.

The stone surface for cutting with high-tech style or with the classic design of kitchen rooms is harmoniously combined.

A medium-sized natural marble slab is ideal for rolling dough, since its natural coolness will not allow the dough to stick, and it turns out to be perfectly smooth and delicate. For the same reason, the stone surface will become an indispensable aid in tempering chocolate and creating exquisite desserts.

A wide range of domestic and foreign manufacturers of cutting boards made of artificial and natural stone provide a wealth of choices that meet all needs - from the classic kitchen accessory to high-end design developments with additional supports, notches for draining excess liquid and so on.

Care

To clean the finishing surfaces of natural or artificial stone is not recommended to use detergents with aggressive components, which include alkali, chlorine and acetone. Despite the fact that the surface of artificial stone is relatively resistant to chemicals, prolonged contact with aggressive detergents can gradually destroy the composition of their coating.

Cleaning granite cutting boards should be done manually using dishwashing detergent. In the similar way washing of finishing surfaces from any other natural stone is carried out.

For disinfection, stone surfaces can be treated with vinegar, soda or lemon, then rinsed with water and wiped dry with a soft cloth.

In general, stone cutting boards do not require any special storage conditions. For convenience, many of them are equipped with special handles or rings, with which the product can be mounted on the kitchen wall. In the absence of such elements, the boards can be stored in boxes or simply on the working surface of the table top.

It is necessary to store kitchen equipment made of artificial material separately from the boards made of natural stone to avoid mold and scratches on the surface. For long-term preservation of an attractive appearance, the stone cutting board needs to be polished periodically.

Adhering to the simple rules of care, regardless of what material the cutting board is made of, it will be able to please the hosts with a long service life, retaining its original color and glossy shine.

Advantages and disadvantages

According to reviews of users of stone cutting boards, one can identify their main positive features:

- stone cutting surface has high wear resistance: does not crumble, does not stain with products;

- durable stone surface repels liquids and dries quickly;

- does not absorb smells and juices of products, fits snugly to the working surface and does not slip;

- exquisite and stylish appearance;

- a variety of colors and shapes, which allows you to choose a board that fits perfectly with the kitchen interior.

Of the shortcomings of stone cutting boards, users point out some qualities.

- Significantly higher cost compared to boards made from other materials.

- The need to sharpen knives more often, which leads to a rapid deterioration of their functionality (the blade becomes thinner).

- The kitchen surface from a natural stone has "notable" weight. Thus, the average board with a thickness of about 1.5 cm weighs from 1 to 1.5 kg.

- It is deformed from too high a temperature, therefore, it is not recommended to use a stone board as a hot stand.

- Prolonged exposure to natural acids that make up fruits and vegetables, over time, destroys the surface.

The many advantages of stone chopping boards over similar products made of plastic, glass or wood cannot be ignored. Reliability and quality assurance of such kitchen accessories is confirmed high functionality, long service life, ease of use and care, as well as numerous reviews of happy users.

Some fans of culinary art believe that stone boards are suitable only for rolling dough, and some, on the contrary, use such surfaces for cutting, serving and serving dishes. In addition, the cutting board made of natural stone is a very expensive luxury, but each owner of this accessory will be able to emphasize their status and sense of individual style.

High-quality cutting board is an indispensable item when cooking a variety of homemade dishes or delicacies. Which one to give preference depends on individual needs, set goals, as well as the financial capabilities of the culinary specialist.

An overview of the stone boards, see below.