Adults and children like it when the cake, cake and other goodies are decorated with various chocolate figures of different shapes and sizes. It is always tastier and more interesting to eat fancy shaped chocolates in the form of animals, machines, bows, hearts and others. In the article we will tell you how to please your relatives and friends with home-made candies of our own production.

Materials

Almost every second hostess is now experimenting with homemade chocolate and chocolate candy recipes. Special skills are not needed for its preparation, there is nothing complicated about the recipes, but those who have come across manufacturing know that the important tools for this are molds for casting. They differ in the material of manufacture and are:

- silicone;

- polycarbonate;

- metal;

- plastic.

Which of them is better to choose and how they differ - consider in more detail.

Silicone

This material is famous for its environmental friendliness and low cost. In addition, it is ideal for pouring curly jewelry from chocolate, and for the formation of ice. Silicone is not afraid of either cold or hot drops. It can also be used for an oven at a temperature of 230 degrees Celsius and for a freezer at minus 40 degrees, the material will do an excellent job.

The advantages also include the fact that silicone molds do not absorb odor, wash easily even without detergents, do not react with other products.

Safe and pure medical silicone is used in the manufacture of such products, so it will not release any harmful substances, respectively, you should not worry about the quality characteristics of products made in silicone molds.

It is also convenient to store because very plastic base. It is easily rolled into a tube, while the product does not lose shape and never deforms. And also this form is convenient when removing products - it can simply be turned inside out without fear of tearing. This is well suited to beginners, as there are often problems with this, and pulling out pastry products is difficult at first.

With the help of silicone mold, you can cast a large egg, geometry, dolls, rabbits and many other figures.

Choose to your taste - and create. Finally, on one such form there can be from one to several varieties of figured cells, which makes the manufacturing process fast and the product varied.

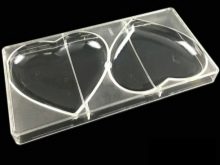

Polycarbonate

More suitable for professional confectioners. This form has a price higher by ten times than molds made from other materials. But a person who is keen on the process of casting all sorts of chocolate jewelry and sweets in large quantities, it is this form that will make this activity very fast, because such a container does not need to be oiled before use.

Polycarbonate forms have several advantages:

- easy to wash;

- with frequent and long operation, they have no deformation;

- high or low temperature conditions they do not care;

- polycarbonate does not give smell and taste to the products and is not saturated with any odors;

- easy to operate.

In addition, there are Polycarbonate molds with a so-called magnetic bottom. They are used by confectioners in factories. Very easy to use if you need to make a large number of twin candies.Earlier, when there were no such blanks, the confectioners had to manually apply a drawing or a 3D figure to each candy and they were not always the same, because no one canceled the human factor.

With the help of a polycarbonate mold you can cast such figures as a chocolate bunny, candies in the form of letters of the Russian alphabet, foreign letters and numbers, various flowers, such as tulip, chamomile, rose. And it is also possible to cast various geometric shapes, such as a ball, a star, a rhombus, a hemisphere with various notches, which gives sweets an even more beautiful look.

Metallic

At the moment, such forms already can hardly be found in stores and even on the InternetBecause silicone and polycarbonate are more popular. Although the market price of metal fixtures is significantly lower than other analogues. This form is also resistant to different temperatures, can be washed in a dishwasher. When washing You can use a metal brush if necessary, and it does not harm her. It is durable and will last for decades.

This leads to the conclusion that it is simply unprofitable for manufacturers of molds to fill the product at a low cost, but it has served for many years. In addition to chocolate products, biscuits can be made in this form, giving them fancy silhouettes.

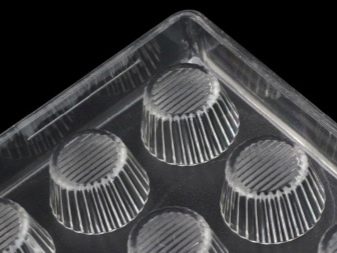

Plastic

To mold a bar of chocolate, it is used such. It is made of flexible plastic, easy to use and fairly cheap, but it is worth considering that over time this form is deformed. And it is small, and it is impossible to make chocolate with filling in it, unlike all other varieties of chocolate molds.

How to use?

First of all, a new product for pouring chocolate should be thoroughly washed in warm water using detergent and then dried completely, otherwise the chocolate will stick to the walls and bottom.

Melted chocolate pour not to the brim, but 1/3 of the cells and check for the presence of air bubbles. To get rid of these bubbles, as well as to evenly distribute the mass in the whole figure cell, you need to gently knock the shape on the table.

To make it easier to get candy, silicone mold can be turned. And on plastic, polycarbonate and metal it is enough just to knock on the bottom, turning the mold so that the products spill out on a towel or soft cloth.

No need to touch the finished chocolate with your hands to help get it out of shape. From this there are quite unsightly traces. Wear gloves or do it, trying not to touch the products.

For information on using chocolate molds, see below.