Cutters for hardware manicure: varieties, purpose and tips for choosing

Apparatus manicure is considered quite hygienic and simple procedure that allows you to make your nails beautiful without the help of cutting tools. If you learn to use it, the device will become an indispensable thing. Neil masters from all over the world have already appreciated the beauty of working with a manicure machine.

What it is?

Turning to a beauty salon or to your master, you want to see only the best result. Undoubtedly, the industry has made a huge leap forward, so the technology touched even the field of manicure. There are two types of manicure: trim and hardware. In contrast to the edged, hardware manicure looks more neat, and the process of its application does not cause pain.

If the usual cut manicure uses nail files, orange sticks, pushers, buffs, small nail scissors, tweezers, cutters and many other tools, then in a manicure with a machine you just need a special device - an apparatus that looks like a thick pen. Such a device is called a milling cutter or milling machine.

In order for the router to perform actions of different purposes, it is necessary to use various types of nozzles: cutters, drills, burs, polishers and others. Such devices are usually bundled, but advanced masters buy them separately (depending on the tasks that must be performed using them).

Manicure and pedicure for their high-quality performance require different nozzles, different cutters. These tips can be made with different textures or made of different materials. Most often, each device is described in the form of instructions for use, so it’s not hard to figure out what's what.

The main advantages of the hardware manicure is its painlessness and speed of execution. You can not believe that this procedure has no downsides. Hardware manicure is just beginning to develop, so not all masters know how to work with a router correctly. In addition, it is necessary to choose the nozzles correctly and sterilize them qualitatively before each new application.

Classification and purpose

As we have said, nozzles for the router are divided into several categories:

- blunt cutter;

- narrow end (or fissure) cutter;

- mill with a sphere-like end;

- mill with corn-like end.

Each type of cutter is designed for its own goals and objectives. Often use universal or combi nozzles.

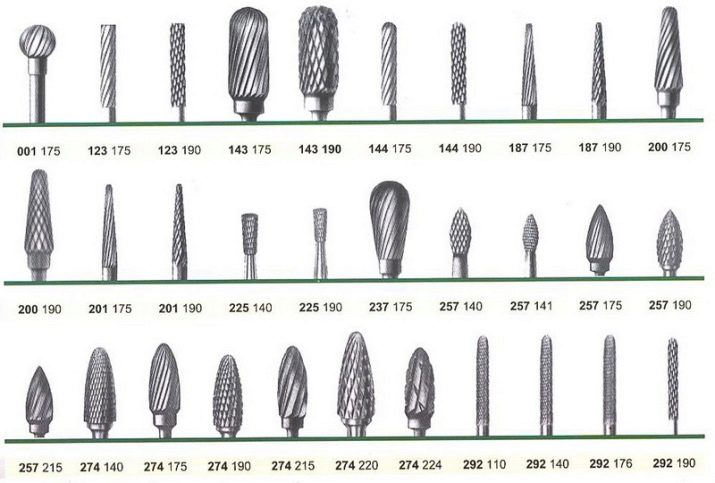

In form

Cutters vary in shape.

- Needle - can be attributed to the fissure type. The name given to them because of the appearance, resembling a needle. Needles are needed to work with rollers - areas between the nail and the skin, as well as when removing the lower layer of the cuticle - pterygia. The diameter of the needle cutter does not exceed 2 mm. This is not the safest attachment, because working with the cuticle and pegrium should be extremely neat so as not to touch the excess skin and cause bleeding.

- Reverse cone perfectly aligns the plate, but is still more often used in pedicure to remove small corns.

- Ball or boron - this mill up to 2 millimeters in diameter allows aligning the line of the cuticle, polishing the cracks on the enlarged nail and processing the space between the skin and the plate.

- Rounded Cylinder happens narrow and wide diameter. Narrow allows you to process the skin around the nail, wide - remove the gel layer, adjust the plate or process the side rollers.

- Pointed cylinder (bullet or bullet) prepares the nail for the future design.

- Flame - This is the only universal cutter. Suitable for beginners or home use.

- Cone allows you to make a form for a non-natural nail.

- Frustum - A great solution for rough and rough skin, hard and extended nails. It can also be used for pedicure.

By material

Each type of tip can be made of different materials, it also plays a big role in creating a new manicure.

So, corundum and diamond mills made of ceramics or hard alloys are distinguished, there is a category of carbide tips, garnet or silicon-carbide mills, and silicon and even steel mills are also on the market.

There is an indicator of abrasiveness - hardness of spraying. Usually it is determined by the label on the handle. There are several colors of abrasivity.

Metallic

The category of metal mills include all hard alloys, as well as carbides, steel. Such nozzles are used mainly for enlarged nails or hardened skin, since they can damage natural nails due to their stiffness. The difference of metal cutters from the rest is that they do not cut, and cut off the layer of the nail.

The rigidity of the work is determined by notches. They can be straight, oblique and cruciform. It is considered the most rigid cutter with straight notches. The notches are applied to the mill by cutting or stamping, and then the element is treated with oxides (this is necessary in order to prevent subsequent rusting and deformation).

Metal nozzles - one of the most versatile nozzles, because they are designed for the nail plate, and for skin treatment.

Diamond

If metal cutters are an option for artificial plates and coarse leather, then diamond mills are designed for thin leather, cuticle and natural nail.

The abrasiveness of the diamond nozzle is determined by its color. A light mill indicates the softness and safety of spraying, dark gray - about hardness and pronounced grains.

Diamond spraying can be natural or artificial - the price of the product depends on it (natural diamond spraying is more expensive, but the quality of its performance is higher).

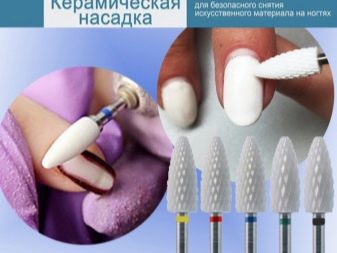

Ceramic Cutters

Usually they are immediately included in the kit for a milling machine, because they are suitable for both home and professional care. Ceramic elements are needed for the treatment of dry skin, corns.

Abrasiveness is also determined by color: white, blue and black. Black is the toughest, its index is 400 microns (that's why it is often called “artificial pumice”).

Combined

These silicon carbide cutters are the perfect start for newbies. It is considered that such caps are disposable, therefore they withstand only 1 procedure.

The type of material and abrasiveness is the key to a successful manicure.

The cutters themselves are not expensive at the cost - from 50 rubles for 1 piece. The better the quality, the higher the abrasiveness, the better the brand - the higher the cost. Cutters are sold complete, sets or individually in professional and amateur stores.

Tips for choosing

In order to choose a quality mill, With the help of which you can make a beautiful and neat manicure, use some tips.

- Determine what you need a cutter for: manicure or pedicure. From this depends largely on what material to choose and with what characteristics.

- Determine for yourself what use your device will assume: home or salon.So, for the salon will need more cutters, they should be of better quality, because the device will often be used, and consumables - not a cheap thing.

- Choose cutters for a specific machine. The fact is that the twisting force is different for everyone, the apparatus itself can give revolutions of 1500 and more (the wear of the mills depends on this). For home use, the cutters can be used from a set and will not be replaced for many years.

- Choose devices that control the overheating of the cutter.

- Always pay attention to the diameter of the cutter. Small cutters should work at high revs, and large - at low.

- On some types of nozzles there is the letter "T". This means that the element is coated with a substance that increases the cutting ability.

In general, to accurately determine the qualities of the cutter, you can use the ISO standard. Also pay attention to labeling - they describe the properties.

For each action with the nail, nail plate, cuticle and the skin around the nail there is a separate nozzle. If you use the nozzle for other purposes, you can not only not achieve the desired result, but also greatly damage the nail, both aesthetically and physically.

Below are the basic actions of the cutter during a hardware manicure.

To remove the cuticle

Cuticle removal involves the use of several types of cutters. The cylindrical cone allows not only to raise the cuticle, then to remove pterygia from under it. Blunt-pointed cutters are designed for lifting the cuticle and cleaning the nail as a whole. Narrow-pointed - designed exclusively for the removal of pterygia. Then a spherical milling cutter is used - it allows to treat the sites of cracks or tears of the cuticle.

Gel polish remover

Tip "corn" easily copes with extended nails, removing even the thickest layer of coating. It is better to choose a mill from hard alloys - this will save time (and the acquisition of new nozzles will occur much less frequently).

The principle of the "corn" is to turn the gel polish into chips - notches on the mill, rotating, cut down some of the varnish. Choose elements with deep notches - this will preserve the quality of the cutter for a long time. Volumetric grooves are not clogged so often that makes it easy to clean the tool.

Also, "corn" can be used in shaping the nail when building. Modern masters prefer the "corn" of ceramics, because it does not cut chips, and turns it into dust. In addition, ceramics is 4 times stronger than alloys.

For shaping

To give shape to an artificial nail, everyone also uses “corn”, a truncated cone can also be used. For a natural nail, use a reverse cone or cylinder. This is the easiest set, which should be even for home use.

For polishing and grinding

The sphere-like end polishes a nail, polishes it, and also protects the cuticle lifted by a blunt cutter. It is important to know that for polishing rubber or silicone cutters are most often used - it is important not to damage the nail, not to remove the stratum corneum and not to cut off the cuticle, but to polish the nail until smooth, to prepare for further coating.

In general, such nozzles - a storehouse for a novice master. With them you do not exactly damage the nail, do not spoil the shape, but only learn to work more confidently with the device, gradually learning all the subtleties of the hardware manicure.

Nozzle Selection Criteria

An important criterion in the selection of cutters for hardware manicure is your qualifications and experience. Experienced craftsmen can experiment with nozzles, their shapes, stiffness, notches. For a beginner or for home use, the standard cutters included in the kit are sufficient.

Pay attention to the material - as already mentioned above, the new generation of ceramic nozzles last longer. Those who are just starting can choose classic samples of materials that they should not be thrown away after a quick erasure or if they are not suitable for you to use.

Start with less hard abrasives. The stiffer the nozzle, the faster the manicure procedure, the faster you can achieve the desired effect or spoil the nail. To begin with, use the lowest stiffness, and only then choose a comfortable abrasiveness for yourself. Remember that you can identify it by color on the handle of the cutter.

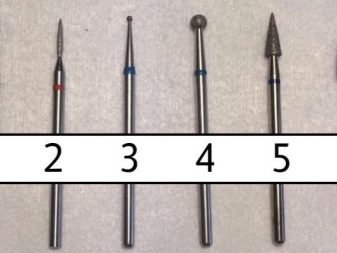

For initial use and mastering of hardware manicure, you can refer to the following tips:

- white sanding nozzle;

- choose a red nozzle to work with pterigium;

- For cuticle and skin treatment, give preference to green;

- for artificial coatings and gel polish removers suitable blue color.

It is important to select the nozzles that are suitable for your device. You should be comfortable and comfortable working with them so that neither you nor the client have any unpleasant feelings or emotions.

Instructions for use

In order to properly use the machine, follow the simple instructions.

- Take the manicure machine out of the box.

- You need to insert the nozzle into the machine until it stops, it should be tightly fixed with a clip inside the handle slot.

- There are three types of clamping cutters in the socket: automatic, rotary, screw. With automatic clamping, you just need to insert the nozzle into the handle slot. When turning the clip after inserting the cutter into the slot, you must turn the ring at the base of the slot. The device with a screw clamp is the easiest to use, therefore it is suitable for home use. In order to fix the cutter in the socket, you need to turn the base of the socket all the way, as if screwing the element into the handle.

- On a professional milling machine, there is a function to select turns, if you are just starting your way - do not set the speed above 6-10 thousand turns, because due to lack of experience you can damage the plate and the skin at that speed.

- Keep cutters in one place, preferably in a box with graduations adapted for this. So you will never lose them and you will always know where this or that nozzle is located.

- Do not press the cutter to the nail - it is intended only for cutting off keratinized layers or outdated gel polish.

Rules for cleaning and sterilization

Disinfection of the elements of the device and sterilization are important actions at the completion of manicure. Typically, cleaning is carried out in several stages: disinfection, cleaning from contamination, boiling or re-disinfection. Each of the stages should be carried out carefully, observing all the rules, so that all bacteria are destroyed, and nothing foreshadows the next client infection.

Each type of cutter material must be disinfected in its own way.

- Metal elements are immersed in the solution at the required temperatures. Remember that if the temperature is too high or the concentration of chemicals is too high, the metallic elements may become deformed, leading to the utilization of the cutter. Then you need to thoroughly wash the elements to wash away the concentrate. You can also use the oven. For the concentrate, 30 grams of potassium permanganate, 100 milliliters of 70% medical alcohol and 10 grams of boric acid salt are used, and manganese is added after mixing. You can also use ready-made preparations: Kutasept F, Octenisekt, Sterillium.

- Ceramics and diamond dusting is easily disinfected in special ovens or autoclaves.

In general, even if you are a “master at home”, then you should purchase an ultraviolet lamp or an oven. This will make it easier for you to clean the elements, and you will not be sure that your device is sterile.

Recommendations for replacement

Replacing cutters occurs according to the degree of grinding abrasive.According to reviews of professionals and amateurs, the metal elements of the cutter grind off for 3-5 years (depending on the frequency of use and the number of revolutions at which the machine works) High-quality diamond plating with timely and proper cleaning and processing will last up to 3 years. Ceramic nozzles are short-lived (only two months of regular use), but silicone or rubber are replaced as they are completely erased.

Most often the ceramic nozzles are included in the kit. Their quick grinding will allow you to understand the essence of the work, and later acquire those cutters that will be convenient for you to work with.

Also, the time of operation depends on the correct change of nozzles. If you have a professional device, then you just need to turn the element in the slot of the cutter. If the device is home, then you need a special key, which often comes bundled with the machine. Be careful here, it is possible that you twist the clamps - then the nest may crack. In this case, you will have to completely change the whole pen or even the whole apparatus.

Thus, you got acquainted with what types of cutters for hardware manicure are present on the modern market, as well as studied their features and characteristics. You also learned about the rules for their selection and operation. Do not neglect this knowledge and pay attention even to those details that at first glance seemed to you irrelevant. Be careful, because the wrong choice of cutters can lead to delamination of the nail and deformation of the nail plate, which in no case can not be allowed.

Review of cutters for hardware manicure, see the following video.