Knives - very useful tools that can be useful in the household, creativity or even in repair work. They have been used by man since ancient times, and over time they have only been modified. But, like all good things, knives also have a minus: they need to be sharpened from time to time, and today you will learn how to do it correctly.

Varieties of fixtures

There is a huge number of possible options that can help in everyday life, at work, in factory conditions - wherever knives are used constantly. These items can help in sharpening a diverse character, and each of them is in its own way good and convenient.

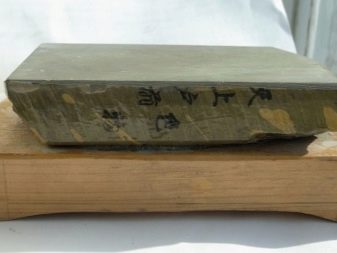

Grindstone

The most ancient and primitive devices for sharpening knives are the usual natural grinding stones. However, today this method will not be the best, it can be used only for sharpening a hunting or kitchen knife. There are also other, more accurate options: water or "wet" Japanese stone - novakulit.

It is slightly more convenient to use, but still it will not be possible to use it for frequent and quick editing.

This stone should be used in combination with a special oil base. Of course, there are his domestic counterparts based on ceramics, however, the original will be the best choice. By the way, in the case of the Japanese grinding stone, its even surface is very important. You can check it this way: wet one side and put it on a piece of paper. If the print on paper is perfectly even, and evenly distributes the trace over the entire surface, then the tool is of high quality.

Sharpening stones are primitive ways to sharpen some kind of penknife for going to the woods or to fix kitchen equipment once a couple of months.but if you possess something more serious, the stones will not suit you.

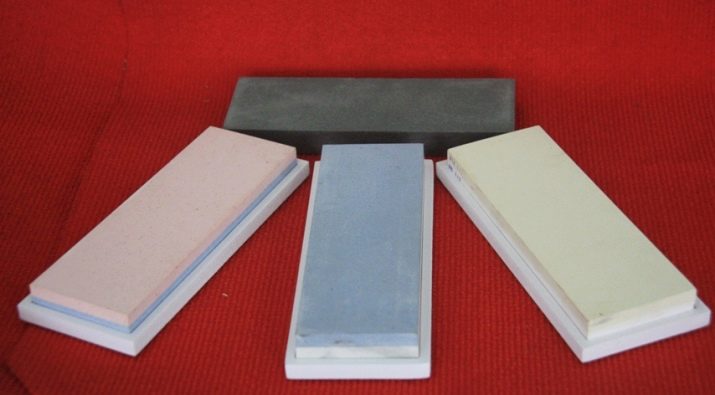

Bars

There are other devices that will help bring your tools to their original state, "as from the factory" - abrasive sticks or muds. They differ in the coatings that are applied to them. If we talk about the differences of such bars, then there are quite a lot of them.

- Diamond coated - There are options for various forms, and even dusting grain. Despite the diamond coating, their price is not very high, it can even be called democratic.

- Ceramiccombining the properties of grinding stone and diamond deposition.

- Artificial stone - here the duration of use leaves much to be desired, but the prices for such stones are much lower. This option is created when mixing the powder of diamond origin with carbide, and it is important as the ratio of substances, and adhesive. Even this option can be of good quality, but it is still inferior to alternatives.

If we talk about diamond spraying, then there are two main ways of using and placing it. Any of the layout of elements is called grain.

- A bunch, called galvanic. This crystal pattern is very strict. In this case, diamonds are glued with a thin layer on the entire surface of the base, which is most often created from an alloy of nickel. It turns out durable bar.

- Soft location is characterized by chaos. In this design, it turns out that the adhesive and diamond substances are intermixed with each other and located across the entire surface, but there is no clear structure in this mixture.

This option is not as durable as the first.

Venevian diamonds are a unique name for the type of stones used in such tools. They give the rigging rigidity, allowing you to quickly and well sharpen the knife, with careless handling there is a risk of even scratching the product.

There are also elborovyh bars made using cubic boron nitride. They are more expensive, but they work much softer, and they are not a surface with individual sharpening elements, but a full-fledged working area, where each element of the structure is working.

Musat

Musat - This is a knife sharpener, made in the form of a stick or, rather, a file. This type of tool for sharpening has several advantages. Musat is easier to hold: it has a comfortable rubberized handle and looks more like a screwdriver than a classic grinding stone. It can be stored among kitchen utensils, it is light, and even if dropped on a foot it will not cause damage.

Musat can be both round and oval, but in any case it is much more convenient to hold the edge of the blade along such a “stick” than it does on a large sluggish stone.

For individual cases, you can use tetrahedral products, they allow you to more accurately select the angle of sharpening, and more subtly create the shape of your knife.

Double-sided ass

They are often used for sharpening large knives that can be used to cut any durable materials. The bar has a thick rectangular surface, has a comfortable handle.

Hand Machines

If you do not have the skill of turning knives correctly, and you do not know for sure exactly at what angle you need to hold the tool and carry out the movement, then a special device will do it for you. Such "cars" do not take up much space, and are a body that hides the insides, and a grinding disk on the side, made in the form of a ring. This form helps him to smoothly and evenly distribute the working elements of the structure over the entire surface of the knife. The ring just turns with enough speed, that's all.

In order to make the knife sharp, you just need to bring it in the correct position to the disk. On some models, there is even a special notch, which is located at the right angle to spoil the cutting tool, there are no chances left.

What are the machines?

Units that will help you correctly and without problems to make a blunt knife sharp, set. They differ in size and convenience, and variability of work. For example, you attach the device to the table, twist the knob that drives the disc into action, and substitute the knife at the correct angle to the disc itself.

There is a huge number of solutions for any functionality, taste and wallet. Now you can buy a variety of hand-made Russian-made machines.

The machine, assembled at the factory of his native country, will cost less and is suitable for domestic needs more than completely.

Electric machines

Handheld devices are a fairly economical choice, they will help you solve most of the problems that arise with your tools. However, in the case of the electric option, you can save some time and organize a more comfortable work, which you can even enjoy.

Models will be similar manual, but with an electric drive. The principle of operation is the same, but you don’t have to turn any handle, just substitute the knife in the right place, and the device will do everything for you.

Moreover, there are special models that work even from a battery. It is more expedient to use them in the case when you do some difficult work with a knife.For example, you will need to sharpen several knives in a working day, and then it is much more convenient to simply insert them into a portable device, and in a matter of seconds get the finished result.

“From simple to more complex and professional” - it was with this method that manufacturers were guided by creating machines that are in themselves entire sharpening stations. Moreover, they are as versatile as possible, since they are suitable for working with absolutely any knives.

Such devices have at their disposal various powers and modes in which they can grind the blade. Everything is just as convenient: you simply insert the knife into a special hole, turn on the hardness mode required for a particular metal, and run along the entire length of the knife until the result satisfies you completely.

The security of this solution is high, since any elements that can harm you are hidden inside and covered with a body, therefore any unprepared person will cope with the task.

In addition, the angle of all working areas is already set correctly (and in some models can also be adjusted), which means it is almost impossible to make a mistake in this case.

Professional equipment

This type of tool is suitable, rather, for craftsmen - people who use knives often, and already have experience in dealing with a variety of designs.

If we talk about the manual machine, then it takes quite a lot of space on the workbench, it is usually assembled on its own, that is why it is characterized by unsurpassed accuracy. If the professional knows his business, chooses the right elements, and perfectly selected all the corners, then the accuracy of such a machine will not be equal.

It is necessary to warn unprepared people since the use of this equipment is not intended for inexperienced users.

If you just need to bring a one-time kitchenware into a “digestible” state, then the easiest way to do this is using a simpler sharpener.

There are professional electric machines - this, when compared with the previous options, is “aerobatics”, however, even in the use of such a device is still nothing complicated. It has an impressive size, and the disk is quite wide and massive. Such pieces are used in locksmith shops or houses where there is a private house and household.

The main advantage of this solution is its versatility. This is because such a device will help not only to sharpen a knife, but also to bring into practice practically any working tool made of metal.

The power of the device is more than enough, whether it be just kitchen utensils, a chisel or even the edge of a bayonet spade. On this machine, you can easily handle an ax.

Marking

There is a special type of emery paper that does an excellent job with the task of correcting blade bluntness. Usually a special mount is sold in hardware stores, which can be held comfortably in your hands while working. It is called a blank, and any of the necessary sandpaper sheets can be easily and comfortably fastened onto it.

This option is very convenient for those people who are very rare with the use and tidying up of knives. In addition, this choice is characterized by its efficiency in comparison with any of the above devices. You can choose a completely different paper, it is more or less rigid, it works with different softness, and the blank itself, and the sheet you buy has a wide variety of sizes.

Marking is the name of the parameter, which is responsible for the rigidity of the paper, more precisely, for the number of work items on the piece of paper. It can be 1000, 3000 and higher. The larger this parameter, the more rigid the friction of the two surfaces will be.

Sandpaper can be bought in sets, and use them for all occasions. You don’t have to change them too often, you’ll have enough of one stretch for a few grunts.

What is better to choose?

If you are only thinking about purchasing any of the above options for home, work, etc., then it would be best to start from the needs and plans for use.

A simple stone will lie with you for many years, and if you learn to work with it correctly, improving the functionality of any knife from the kitchen or from a hunting bag will not be a big problem for you. If you are a fan of something special and more comfortable, you can use Japanese natural solution, however, it is not so practical, and is more expensive.

For cooks and people who often use different cutting options, the perfect choice will be comfortable and soft musat, which can be used at least every time before cooking. This way, you better prepare your utensils for work.

People working with sharp objects every day will do well machine toolsthe most convenient of which are electric. Well, if your activity is completely tied to the use of garden utensils or devices for cutting wood, then feel free to take a large professional machine.

Subtleties of application

In order for your tools to please you, and the result did not cause the desire to redo anything, it is important to use all that is listed above.

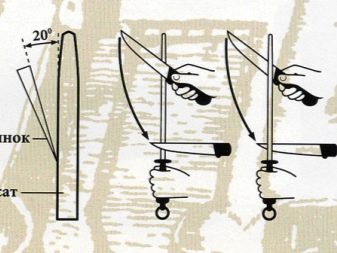

In order to sharpen the knife correctly, it is enough to drive with a working surface. at the very edge of the blade, and not at the thinnest cutting surface. After all, the task is to make it thinner, and if we drive it over the musatu, it will turn out that it will become even flatter and less acute. In case of using a wet stone, it must be lubricated. The instructions for use are more detailed, but in general this requires the use of an oil base.

The angle must also be chosen correctly. Household blades, as well as any kitchen utensils endure an angle of 30 degrees. Indicators vary from instrument to instrument, however 25 to 30 will be sufficient in most cases.

By the way, the machines must be trained before use: you must make sure that the design is not broken, the electricity is supplied correctly, and the machine itself is firmly supported on the working surface.

Frequent mistakes when sharpening

Untrained persons may make mistakes, and one of the main things will be to use the device with which you are not at all familiar, and hold it in your hands for the first time. If you are a beginner, then the best would be ordinary musat or bar.

In addition, you should not try to drive a grinding surface on the blade itself - so its sharpness decreases even more. Do not use professional machines if you need to sharpen a simple kitchen knife, and always choose the right angle at which you work.

To learn how to sharpen a knife on a stone, see the following video.