Samura Japanese kitchen knives are products that harmoniously combine ancient grace and sophisticated aesthetics, convenience and functionality, practicality and durability. This is exactly the case when the ergonomics of the form smoothly passes into the blade perfection.

Brand information

Samura Japanese knives are not just a brand, but a product line developed specifically for Russia. Point of support in the creation of the company and the formation of the brand in this case were the ancient knife traditions of Japan. Having kept the basic parameters of the products of the manufacturing country, accuracy and their high quality, the production managed to adapt the shapes of the blades and handles to the habits of the Russian consumer.

Today Samura is the result of modern production, which uses the best grades of Japanese and Swedish steel., hard hardened to 58 - 61 HRC. The blades of traditional Japanese form, with a subtle note of the butt, provide the fabulous fantastic cutting performance.

The well-thought-out product line of the categories and series of models produced allows us to assemble convenient working kits for both professional chefs and housewives.

Knife Features

Special respect for knives in Japan has developed historically, in the days of the samurai. Technologies of forging knives from ancient masters, as well as the rules for sharpening and caring for cutting tools, have come down to our time and are widely used. The tendency toward perfection, aesthetics and beauty, peculiar to the Japanese, was directly embodied in the art of making cutting tools. Modern kitchen knives largely retained the shape and quality of the blades, and the use of advanced technologies in their production gives the products improved quality characteristics.

A major shift in the manufacture of kitchen tools has emerged in Japan after the Second World War., following the ban on the production of cold weapons. Masters did not have to radically rebuild, but only differently place some accents regarding certain dimensions and geometric parameters in the manufacture of kitchen knives. Today, professional chefs and housewives in Japan produce good knives, including those made from Damascus steel, including new models, traditional ones, and cutting products adapted for Europeans.

In its classic version, Japanese products are different from traditional European models. Characteristic features are: a massive butt of a knife, a more elongated blade, and the use of a one-sided type of sharpening. Moreover, grinding is made to order for both left-handers and right-handers. The narrow blade of Japanese knives allows for more subtle kitchen operations. The use of such knives requires a certain skill.

The main difference between Japanese knives is the quality of steel and other materials used for their manufacture, as well as the design features of the blade. Expensive high-carbon steel is commonly used in manufacturing. Therefore, the blades have a high level of hardness, higher than that of analogs from Europe.

For this reason, Japanese models for a long time retain the quality of the first sharpening and, as a result, the quality of cutting products.

Varieties

Traditionally, preferring the quality of manufacturing products without detriment to other requirements the company sells goods in a number of Samura categories, which we will note in a brief overview.

- Samura Pro-S are high-quality molybdenum-vanadium steel product sets that are popular among chefs. Prices are high.

- Mo-V High Carbon - models of universal application, ergonomic. Budget prices.

- Bamboo - with a unique handle shape resembling a bamboo stem. In the manufacture of special grinding is used, not allowing the handle to slide in his hand.

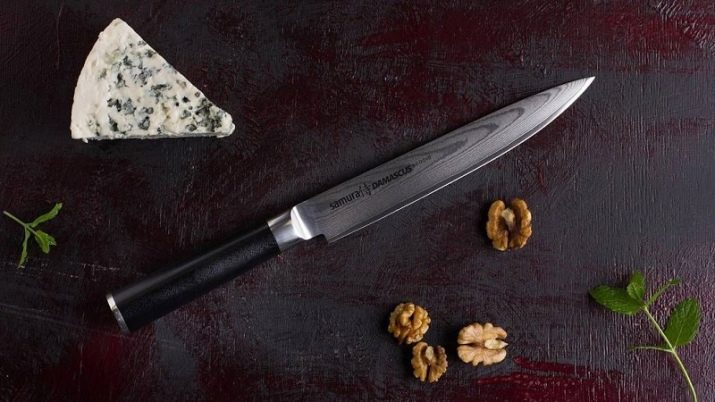

- Damascus - a set of models with a thin blade of steel, equipped with Damascus plates for delivered and a long cut.

- Tamahagan - made using katana sword technology. They have 33 layers of steel, reinforced by the composition of vanadium and nickel.

- Harakiri - equipped with unconventional handles of acetal resin, with a perfectly balanced blade.

- Mac Black Fuso - reliable cutting tools with Teflon coating.

- Mac Original - products with excellent ergonomics and unique design.

- Mo-V High Cargon / G 10 - modern products with high anti-corrosion qualities. The handle is made of fiberglass;

- Segun - the original models with laminated blades and glass-ceramic handles.

- Ceramotitan - products made from the original composite composition with ceramic blades and durable titanium coating.

- Eco-ceramic - comfortable and practical ceramic models.

- Fucion - products with ceramic blades and plastic handle. Stylish, ergonomic and reliable.

In categories you can select the most popular series.

- HARAKIRI - a series of knives made entirely of single-layer steel, which are quite affordable. Harakiri knives are especially popular with beginner chefs because they provide an opportunity to assemble a good working set of knives at a relatively low cost.

- DAMASCUS. The professionalism of the masters of Samura is perfectly reflected in a series of Damascus knives - high-quality, reliable, durable and very comfortable products. Applied steel is prepared according to the original recipe, according to the latest technologies.

- ECO-CERAMIC - a series of classic ceramic knives of low cost, made in a minimalist, restrained Japanese style.

- CERAMOTITAN - keramatitovanny products, not afraid of blows. They are widely used by professional chefs in institutions with a large number of clients and significant amounts of work.

Each of the specified series includes knives of a wide range of mission (sirloin, nakiri, santoku, chef's knives, etc.).

With the advent of the latest technology, the company has mastered the production of zirconia knives. These lightweight products have enviable strength, hardness and durability. They long retain a high cutting ability, are not susceptible to corrosion and aggressive media, are extremely convenient in operation. Ceramic models are produced by sintering in special melting furnaces.

For zirconium and other ceramic cutting products, there are certain rules of operation: you should not use them for cutting bones and other particularly hard products. They are not intended for chopping or scraping. It is impractical to take them with you for hunting or fishing - ceramics are effective only in the kitchen.

Knives "Samura", made of Damascus steel, durable, flexible and equipped with a highly sharpened blade. Here, high quality is ensured by combining and creating multi-layer products from various grades of high carbon and alloy steels (for example, the Super 5 five-layer knife series). These products are characterized by a characteristic layered blade structure that provides both strength and beauty of the product. The process of their manufacture is labor intensive and includes a number of stages, which affects their relatively high cost. However, the long service life justifies the purchase of these knives.

Recommendations for selection

Choosing a knife for the kitchen, it is necessary to consider, first of all, the material from which the tool is made.The optimal choice depends on the financial possibilities (the cost of the product) and the quality of the product, its strength characteristics and durability. Perhaps the most elite cook knives are knives made of Damascus steel, for the manufacture of which uses sophisticated technology. Such knives can serve tens of years and will not become useless.

Steel knives are made in single-layer or multi-layered versions. What matters is the carbon content in the steel of the knife. Japanese knives made of steel are effective, durable, easy to clean and quite affordable. Ceramic knives are inexpensive, effective, but require special care. Shots should be avoided since chipping is possible. Accuracy in handling such a knife will be absolutely not superfluous.

An improved version of ceramics is keramomitan - it is more shock resistant.

In order to choose the right knife, it is important to clearly understand for what purpose it is needed. Among the knives "Samura" there are different types, distinguished by their areas of application.

- Universal knives. In the classic Japanese version, they are called Santoku and may have a wide or narrow, medium-length blade. Steel for the knife blade and material for the handle is chosen depending on the specific situation and the cost of the blade. Sharpening the blade is made in a straightforward manner and can be two-sided for easy operation. In addition, this sharpening of universal knives ensures the excellent sharpness of the blade, which is preserved for a long time. Often do not have to sharpen the blade.

- Knives for fish and meat - an extensive category, including filet knives, for cutting steaks and separating meat from bones, etc. Combines these knives into one category their purpose. The length of the blade in the category depends on the specialization of the knife. However, more often the blade will be straight, with possible bends along the internal lines of the contour (the upper edge remains flat). Steel is usually applied multilayer, the blade is hard, but not always. For example, boning kitchen knives are quite flexible.

- Other types of knivesincluding auxiliary functionality, represented by knives: for bread, tomatoes, fruits, cheese, etc. In each case, they have their own specific features.

How to distinguish a fake?

Fakes in our modern life, unfortunately, are not uncommon. It is especially important to be careful if you purchase a branded and expensive product. In some cases, it makes sense to find a product photo on the brand's website and carefully compare it with the store copy. Carefully inspecting the goods, it is important to consider that the fakes usually present themselves in the design details and their appearance.

When buying a product, you should carefully examine the logo, its location, color spectrum and other parameters. It will not be superfluous to familiarize yourself with the opinion of experienced people who have fallen into such situations on the Internet. Look at the letters - fakes of Chinese origin often contain a large number of grammatical errors and typos. The presence of smeared lines is a sign of a fake.

Before buying a product, you should carefully read its description on the site. Any discrepancies in the description and appearance of the real product should be suspicious. Knives are available with individual serial articles, which are easily checked for their compliance with the standards of the company. It would not be superfluous to study the accompanying papers for compliance with the article on the package.

The mini-defects in the appearance of the goods are also quite informative: inharmonious parts, small chips and uneven surfaces of the blade, sharpening defects, poor-quality case, careless packaging with a defective seal Products should please customers with their design.

It is advisable to purchase products in the respective company stores, which gives a one-year warranty and often provides subsequent support.

Storage and care

Traditionally, the blades of Japanese products Samura perfectly balanced and have a special angle of sharpening. To do this, use exclusively special tools - grinding water stones. Sharpen knives should be in three stages.

- Editing is made of stones with a grain size of 300-400. The stone is moistened and then sharpened by double-sided cutting of the blade on the surface of the stone at an angle of 25 ° until the moment of occurrence of small burrs. Further, by unhurried motion on one side of the blade, we align the blade sharpening, and on the reverse side we remove the burrs.

- For the main sharpening we use stone with a grain size of 1000-1500. The sharpening process repeats the contents of the operations of the first stage.

- For the final finishing, stones with a grain size higher than 3000 are used, finishing it with neat and smooth movements on one side.

For sharpening ceramic products, special diamond-coated tools are needed.

To guarantee the preservation of the angle of sharpening and preservation of the geometrical parameters of the blade, it is better to resort to the help of masters.

Any good thing requires proper and systematic care.

- Classic knives, even made from good steel, must be cleaned after working with wet products. Otherwise, they form a raid. In addition, water contains chlorine, which reduces the level of anti-corrosion protection, which leads to the destruction of the blade surface.

- Always clean the knives immediately after use, without leaving the product contaminated for a long time. Washing procedure is best done manually.

- Competent sharpening - a guarantee of long-term operation of the knife. You can do it yourself, so give it to the grind professionals. The final decision depends on the characteristics of the product - expensive knives are better to trust professional craftsmen.

- Caring for Damascus steel knives is in many ways similar. Store the product must be in a dry place and avoid contact with it acidic or alkaline substances.

- Kitchen knives, as well as their sets, it is more correct to store in special stands - it is practical and convenient. Damascus knives should not be stored in covers for a long time.

- The best option for cutting board are wood or plastic products. Boards of glass, as well as cutting on a plate, dull the blade.

- Cutting frozen food or cutting bones is not for knives. It is better and more convenient to use for this hatchets or special knives.

In the next video you will find the knife test Samura 67 SD67.0023.