The meat grinder is one of those items that are present in every kitchen, every hostess. For cooking your favorite dishes, it is simply indispensable. Whether it is an electrical device or a mechanical one, knife sharpening is needed to the same extent in both cases.

The principle of the knife

As already mentioned, there are manual and electric meat grinders. But regardless of the drive, the principle of operation is exactly the same. The electric meat grinder differs only in that it works from electricity, and in a mechanical model, the handle will have to be turned by itself.

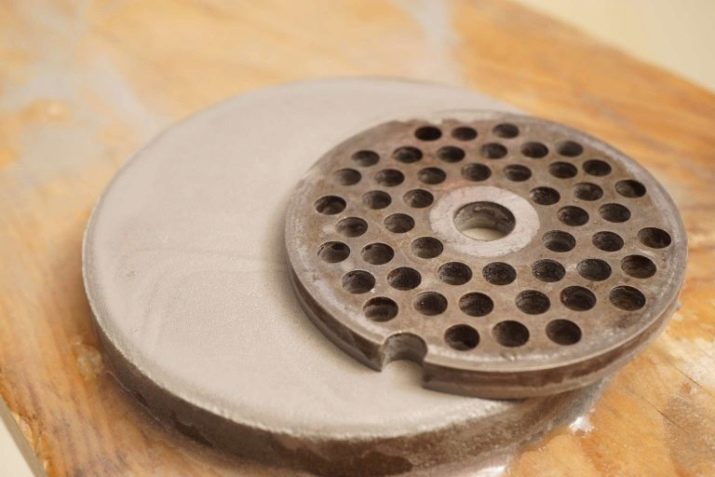

Despite the process of improving the grinders, each of the models is equipped with a flat fixed knife with a lot of through holes (in the operating instructions it is also called a grid or grill) and a knife, shaped like a screw, which has four blades.

The process of grinding meat or other products both in the meat grinder and in the mechanical model is carried out by rotating the cross-shaped knife, which drives a special screw. A part of the product is separated from the main volume and ejected through the holes under pressure. Depending on the diameter of the holes, the stuffing turns out to be a different fraction.

An important factor here is the very tight junction of knives to each other over the entire surface.

There should be no distance between the cutting blades of the cruciform and mesh knives.

The quality of the product issued depends on it directly. As a rule, both of these elements are blunt at the same time, but still the four-blade knife dominates the cutting of meat, and its sharpness must be monitored to a greater degree.

When need sharpening?

As a rule, the understanding that this is required arises in the midst of using the device. Grinding products becomes more difficult, especially if it is a manual meat grinder (the handle is difficult to turn).

The meat can be turned idle, more juice is squeezed out of it, the veins are wound on the auger, and the stuffing itself turns out to be similar to gruel. In addition, if the knives have become dull in the electric model, then it begins to spend more electricity on the grinding process. But the worst thing is that the engine overheats in this mode of operation - your meat grinder may fail completely.

If the listed cases have a place to be, then it's time for sharpening. But do not get upset about it, stop cooking dinner and run to the store for new knives. It is quite expensive, and not necessary.

It is quite possible to handle sharpening with your own hands, even for a woman who does not have such experience, and not to waste time and money on the purchase, the work of a master.

Despite the fact that the manufacturers of this unit claim that the service life of the knives is endless and they self-sharpen by rubbing against each other in the process of twisting products, in fact, everything happens differently. To get started is to understand why the knives are blunt. There are several reasons.

- The steel from which they are made is completely ordinary; even in expensive electrical appliances, it can rust and oxidize over time, which causes them to dull.

- In meat grinders, meat products are most often twisted, which have a soft structure, but nevertheless small, crushed bones, cartilage and tendons are periodically found in them.They contribute to the gradual blunting of knives.

Ways

There is always a choice of exactly how to fix this problem:

- give to a specialist;

- sharpen yourself;

- buy new ones.

It is more expedient, faster and cheaper to cope with this at home.

Consider how to sharpen knives manually.

With abrasive stone

Surely you have a grinding stone at home, if not, then you should get one. By the way with some modern models of meat grinders, it comes in a set, but it is also available commercially. The stone must be new for better effect or not used before for sharpening ordinary knives and other objects, otherwise its surface may be damaged by chips and scratches, which will negatively affect the knives from the meat grinder.

Its grain should not exceed forty - sixty microns, then it will not leave chipping and scratches on the surface. Put the stone on a flat surface, it is better to lay a dense material under it so that the stone does not slide. Sprinkle with water from a spray bottle or soak for two to three minutes in a container with liquid. It is necessary to constantly monitor that the moisture from the grindstone does not evaporate.

The best way is to do it in the sink under the tap. Thus, you will not need to be constantly distracted and check whether there is enough wet stone to cool the metal.

Now take the knife, place it on the stone, press it firmly and rotate it to the left and in a circle until it reaches the cutting blades to get a flat, smooth, smooth surface. For a better cuddle, use a wooden bar. Carefully inspect after, check for scratches. It is important that the sharpening is uniform over all four surfaces of the knife. If you still see scratches on the cutting part, then grind with fine emery paper.

If there was an oxidation film, then during rotational motions, periodically check that it is peeled off evenly. This is extremely important, as it affects the further work of the knife. After that, do the same sharpening algorithm with a mesh knife.

When finished, do not forget to attach the four-blade knife to the mesh and check for a gap. It should not be.

Now it is necessary to rinse both elements thoroughly under running water in order to wash off fine metal filings, collect a meat grinder and roll a piece of meat. You will immediately feel the difference and see if you have coped well with the sharpening. If not, repeat the whole procedure again.

Using a grinding machine

Perhaps this is the fastest way to sharpen knives, only suitable is not for everyone. It requires the skill of working with this machine, and if you do not have it, then it is better to use a special stone, bar or sanding paper. To use the machine, it is necessary to apply a special GOI paste (number four) with a fine abrasive to the smooth surface of the grinding stone and allow it to dry completely. Only then can you start work.

Start the machine and gently press the blades of the knife to the rotating circle. The angle of inclination of the petals should be about seventy to eighty degrees, the important thing here is to preserve the angles. Constantly it is necessary to monitor the surface being rolled and to allow the metal to cool in time so as not to burn it. Do the same procedure with the grille, but in order to avoid damage to the skin of the fingers, use the same wooden bar for pressing.

It is worth repeating that this knife sharpening procedure is only suitable for a specialist with experience in this case - the newcomer will most likely spoil the part, which will then have to be bought.

With sandpaper

The easiest and most affordable way, as sandpaper can often be found in the toolbox in any home. But even if not, then it will not be difficult to buy it at any nearby building materials store. The abrasive part of the sandpaper should be fine so as not to damage the surface, otherwise additional grinding will be required. The action algorithm is very simple and similar to the previous ones.

Securely fasten the paper on a flat surface, it is best to glue it onto plexiglass or other object. Moisten the knife with water, roll counterclockwise until a smooth surface appears. With the second knife do the same.

If the cutting parts are very rusty, then to save power and simplify the process, you can use a drill. Fix the knife through the hole in the center using a suitable screw and gently at low speeds in the reverse mode of reverse reverse the rust from the surface to a uniform shine.

Subsequent processing of parts to finish the manual method. Do not forget to grind both knives to each other to check the snug fit. To do this, press one knife to the other and rotate, looking at the clearance, so that there is no distance between them. A gap of 0.05 millimeters is allowed. This is the approximate thickness of a human hair. If the gap is larger, then it does not matter how sharp the knives are, they will not work very well. Therefore, it is worth repeating grinding.

Expert Tips

- Experts advise for the best treatment of the cutting part of the knives just before sharpening lubricate them with any edible oil and let stand for five minutes. Suitable and machine, but then thoroughly rinse with a fat-washing agent and wipe with alcohol.

- For uniform sharpening, periodically turn the knife around its axis.

- Pressing while grinding should be done directly on the central part. So you will avoid the risk of shaving off metal on one side more than on the other.

- For a long service life, the parts of the grinder must be cleaned well after use and must be dried on a towel or paper to avoid corrosion.

- Inspection of the grinder should be carried out once a month in order to produce a grinding time.

By such uncomplicated methods, you can return your kitchen assistant to the “battle line”. Observing the advice of experts, you will extend the life of the meat grinder for many years.

How to grind knives of the meat grinder, look in the following video.