Oxford fabric: description, advantages and disadvantages, features of application

Oxford is a rather popular type of synthetic fabric, which is often used for tailoring sports and casual wear, as well as tourist equipment. This canvas is characterized by a special way of weaving threads, which is called the "matting": the fabric is visually a convex squares, which are arranged in a checkerboard pattern.

The surface of the material is treated with polyurethane or PVC, so that things from Oxford become impenetrable to rain and wind.

What it is?

The gunny is a type of special twill weaving of fibers, in which the warp and weft are woven in small groups, rather than one by one. As a result, a specific “chess” texture is formed on the surface of the fabric. One of the existing legends says that peasants in Russia invented the matwho wove this rough matter for a variety of domestic needs, using as a raw material fibers of the plant called "rogoz". Subsequently, he was replaced by bast, but the name remained unchanged.

However, the official version is completely different - the fabric, which is a prototype of modern Oxford, was first obtained in the XIX century in Scotland. For whatever reason, this canvas received the name of one of the most ancient British cities is unknown, but historians say that, a few years later, shirts from this canvas became common among students at Oxford University and to this day remain a symbol of the prestige of this elite educational institution.

Initially, textile fabric was made from pure cotton, by the end of the 20th century, manufacturers began to produce oxford from synthetic fiber, nylon and polyamide were added to it, thanks to which this material acquired new physical and technical characteristics and became widely used in many other branches of human life.

A fundamentally new stage in the improvement of fabric has become its processing by various chemical compounds, The consequence of such additives are new properties:

- hygroscopicity;

- resistance to burning;

- chemical resistance.

And although the new type of matter already differs in many ways from its original analogue, nevertheless, the first name “Oxford” has remained unchanged.

Description and properties

The unique method of weaving fibers allows you to protect the fabric from moisture and pollution in the structure of the fabric itself, Due to this, Oxford has many advantages in comparison with many other types of materials:

- property to repel dirt;

- moisture resistance and water repellency;

- wear resistance;

- increased strength;

- the ability to maintain their physical and technical characteristics at t from -50 to + 115 degrees;

- low level of abrasion of a cloth.

At the same time, it should be noted that the predominance of artificial fibers in modern Oxford can create a so-called greenhouse effect, which is why things from this canvas should not be worn all the time and especially during sports and other physical activities.

Varieties

Depending on exactly which threads are used in the production of linen, there are three types of it, each with its own characteristics.

- Cotton oxford - this material is made using cotton fibers; things made of it are very breathable, hygienic and extremely practical. Usually, autumn-spring shirts are sewn from such fabric. It should be noted that in recent years the technology of weaving from natural fibers is used quite rarely.

- Nylon - quite dense and chemically resistant, but at the same time elastic material. It is distinguished by sensitivity to light and elevated temperature effects, that is, the fabric does not withstand exposure to UV rays. In addition, this type of tissue has the ability to accumulate static electricity.

- Polyester - in comparison with nylon, it is not so flexible and dense, however, it is much more light and heat resistant than it.

According to the variant of weaving of a canvas, two of its variations are distinguished.

- Royal oxford - in this case, rather thin threads are used, thanks to which the fabric becomes smooth, but at the same time very dense. The production consumes raw materials of the highest quality, this version of the fabric is used to make expensive shirts for the business segment.

- Pinpoint - production technology in this case is similar to the previous version, but the raw materials are more coarse and cheaper. Such material is used for the production of trousers and shirts. In addition, the fabric is often treated with special impregnations, thereby obtaining air and moisture-proof material, which is used for sewing windbreakers.

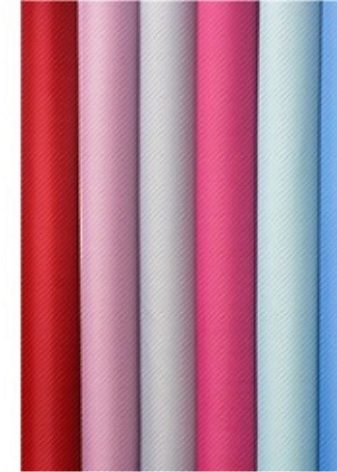

The color scheme of the material depends on the characteristics of the use of the fabric. In the classic version, the fabric has a blue tint, but nowadays it is often painted in green, black and gray, camouflage, oxford can be found a little white, red or yellow, sometimes produce material with an original pattern. In the production of such fabrics, fibers of the most varied thickness are used, and, the denser the thread, the coarser, but at the same time, the fabric becomes dense. Density options range from 150D to 1800D (den).

Benefits

The undoubted advantages of the material include the following consumer properties:

- long period of wearing;

- resistance to damage and wear;

- small weight of finished items;

- budget price;

- ease of care.

Separately, it is necessary to dwell on the water-repellent characteristics of the oxford fabric. In order for the fabric to become hygroscopic, it is impregnated with special polymer compositions, as a rule, after this, a rather thin film is formed on the surface, which makes the product air and moisture resistant. The degree of moisture resistance can be determined by marking the product:

- protection of 200-300 mm - the minimum level of protection, protects only from the wind, does not delay moisture;

- 300-500 mm - indicates that the product is completely wet, only 60 minutes after being in a rainstorm;

- 800 mm - absolutely waterproof thing;

- 1000-3000 mm - the material used for warm jackets, ski suits, as well as tents, has exceptional protective properties.

disadvantages

The drawbacks of Oxford are directly related to what kind of thread was used to make it. So, if the base is polyester fiber, then the main drawback is a slight flexibility in comparison with nylon options. Nylon oxford collapses under the action of sunlight, it begins to fade, and with prolonged contact simply loses its original color. Nylon canvas is sensitive to burning: under the action of the flame, the edges of the fabric begin to melt, but they do not crumble.

For both variants of the canvas, there are common drawbacks that should not be overlooked when purchasing such products:

- the material passes air very badly, that is, simply speaking, it does not breathe;

- Under the influence of low temperatures, Oxford becomes very hard and makes a "rustling" sound as it moves.

All this makes the material unsuitable for the manufacture of everyday and outerwear, and, in addition, sets a limit on its use for creating summer and sports things.

Where does it apply?

The scope of application of oxford matter is directly dependent on the degree of density of the web.

- 150 den - this is the most delicate material, it keeps its shape for a rather long time and drapes well, which is why it is often used to sew raincoats and windbreakers, as well as thin overalls. In addition, the canvas is used for the manufacture of the top layer of jackets, down jackets, bags and covers.

- 210 den - much stronger than the previous one, matter; it is optimal for tailoring tourist tents, sleeping bags, uniforms for fishermen and hunters, as well as lifeguards. Oxford of this variety is commonly used to create workwear.

- 240 den - very dense matter, which is also used for the manufacture of tents, hiking backpacks and awnings. Such fabric is usually impregnated with polyurethane, as a result, it acquires enhanced water-repellent characteristics.

- 300 den - it is a very tough and strong waterproof material, it is usually treated with PVC and sewn bags, suitcases, covers, as well as haberdashery and fishing accessories from it.

- 600 den - Fabric is popular in the manufacture of tent awnings, jackets and other things intended for use in extreme weather conditions. Usually such a canvas is produced in camouflage.

- 1800 den - the most durable and dense type of oxford, it is used for sewing awnings.

Care rules

When buying oxford products, you should first study the information on the fabric care features provided by the manufacturer, since certain types of fabric can be made with the addition of specific yarns that need special care. Subtleties of washing and ironing cloth depend on the main type of yarn used for weaving.

- Cotton oxford varieties are washed in a typewriter with t not higher than 40 degrees, it is allowed to use absolutely any powders. Such products can be smoothed with an iron with a heating of no more than 110 degrees, but it is better to dry them indoors, and at a distance from heating devices, because under the influence of ultraviolet the web changes its shade.

- Products made of nylon or polyester are washed in the same way, but they are ironed in different ways: polyester fibers can be smoothed, but on nylon any hot effect is completely prohibited. When washing it is recommended to give preference to liquid detergents.

- In the presence of any contamination, it is sufficient to wipe the item with a damp cloth. If there is a gap on the canvas, it should simply be stitched or glued.

In conclusion, it should be noted that both men and women recognize the reliability and practicality of oxford products, special emphasis is placed on the duration of preserving the shape of the product, its protection from wind, moisture and the effects of adverse weather conditions. In such clothes it is very convenient and comfortable in the cold season.

In the next video you will find a comparison of oxford fabrics of different density.