Polyamide was invented more than 150 years ago in the USA. It began to be used in industry from the thirties of the last century. The material has excellent technical characteristics: heat resistant, durable, does not corrode. Nowadays it is actively used in various branches of the national economy.

What it is?

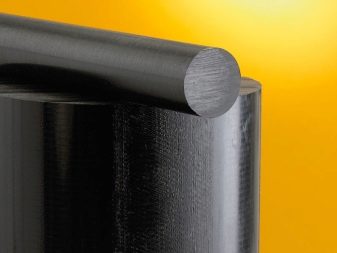

Polyamide is a synthetic that is made from petrochemical products. It is made from compounds that contain the amide group CONH. Polyamide is well resistant to high temperatures, it contains a group of amides, which can be duplicated in a large molecule 8-10 times. The material has a high stiffness coefficient, which makes it very durable. The density of a component can vary in the range of 1.0101–1.233 t / m3. Polyamide substances have gained wide popularity, they have excellent resistance to aggressive substances, can withstand considerable periods of operation.

Polyamide is not deformed, does not break even in conditions of arctic cold and does not melt, staying for a long time under the influence of sunlight.

Features of the composition

Fiberglass material has some of the best performance characteristics for such criteria:

- rigidity;

- density;

- resistance to high temperatures.

Polyamide can withstand temperatures up to 145 ° C, without losing its performance characteristics. This has led to the active use of material in industry (pipelines, dynamic nodes), it can usually be found where there is a high temperature. And also polyamide perfectly resists considerable mechanical loads. Polyamide 6 (GOST 1-0589-87) is an exceptionally stable substance, especially when interacting with aggressive chemical compounds:

- oil;

- engine oil;

- solvents;

- benzenes.

Among the disadvantages of Polyamide 6 is its high moisture absorption rate: the material cannot be widely used in environments where there is a moisture content of 100%. It is very important that after drying the material does not lose its performance characteristics.

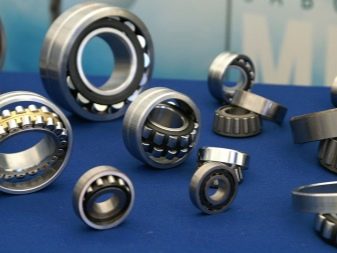

The more dense material is Polyamide 66, it has higher coefficients of stiffness, density, elasticity. It possesses enhanced resistance qualities in contact with aggressive chemical compounds: alkalis, lube oil, fats. Even under the influence of hard gamma radiation, the material does not lose its characteristics. Excellent performance characteristics allow you to use Polyamide 66 in the production of a variety of parts:

- machine shock absorbers;

- bushings;

- bearings;

- wheels

Polyamide 80/20 is widely used in casting, making a preform from it. As well as elements of this composition can often be found in electrical products. Polyamide 12 is used for the production of pipes for public utilities. The material has exceptional wear resistance. Polyamide 12 is often used in the working units of airplanes and helicopters. It does not lose its performance characteristics even when operating in an environment with high temperatures (above 60 ° C).

Polyamide 6 / 66-3 is part of the adhesive joints, as well as film. This material is actively used in the manufacture of natural paper. Polyamide 11 is another functional material that has a high moisture absorption coefficient (0.93%) and has an increased service life. The material does not emit toxins in contact with food, is actively used in industry:

- aviation;

- food;

- automotive.

Unlike other materials, it has a high cost. Polyamide-46 has a unique crystalline structure, the melting coefficient of this material is record high: about 300 ° C, therefore it is used in areas where there are elevated temperature conditions. The lack of Polyamide-46 - poorly tolerates high humidity.

Advantages and disadvantages

Advantages of polyamide fiber:

- maintains weight to 1,6 kg;

- low specific weight;

- practicality;

- colors do not fade from exposure to ultraviolet radiation;

- possesses water repellency;

- not afraid of high temperatures;

- does not spoil from the effects of alkalis and acids;

- it does not harm the fungus;

- does not burn, has a high melting point.

Synthetic products of polyamide group have the following positive qualities:

- strength;

- ease;

- do not crumple;

- easy to wash;

- do not fade and do not fade;

- provide good air exchange;

- protect from wind.

Minuses:

- accumulates static electricity;

- has too high thermal conductivity;

- aggressive compounds quickly penetrate the fiber core;

- Some polyamides interact poorly with moisture.

Although polyamide is not a natural material, it is not harmful to health.

Types and their characteristics

There are many types of fabrics woven from polyamide yarns. The codename of polyamide in the administrative documents of manufacturers - RA.

Polyamide fabrics differ in composition and have names:

- Capron PA6;

- Nylon PA6,7;

- Polyamide PA12.

Polyamide fabrics compare favorably with such qualities:

- ease;

- functionality;

- wear resistance;

- high density;

- low price.

Polyamide is often used in the manufacture of other fabrics. For example, it is added to elastane and viscose. On many labels in the description of the composition of T-shirts, pants, sweaters you can find the word "polyamide". The addition of polyamide to natural fabrics allows things to dry quickly, to be elastic and durable. A dense warm sweater or sweater can contain polyamide additives in its threads. Fabrics can have very different smoothness ratios: polyamide products can be smooth as silk, they can be rough and have a different texture.

Polyamide prices vary widely. Kapron has a price of 265 rubles per 1 kg, polyamide - 420 rubles per 1 kg. Polyamide brand "6" has a price of 620 rubles.

Capron

Kapron is made of Polyamide 6. The material is not exposed to alcohols and concentrated alkalis, has high strength. Kapron fibers are plastic and durable, not affected by ultraviolet rays. Kapron is used in textile production, many garments are made from this material. Often it is used in the furniture industry to create upholstery. Parachutes are made of this lightweight, durable material. The material also successfully replaces sometimes non-ferrous metals, the price of which is extremely high. Low weight and wear resistance allow using this material in the production of cars, trams and trolley buses.

Anid

Anide is made from adipic acid, which, in turn, is obtained from benzene. According to technical indicators, anid is very similar to caprone.

Fabric is available in three types:

- filament yarns;

- monofilament;

- staple thread.

It differs anid the fact that the melting point of the material is slightly higher (+ 226 ° C). Products can be processed at a temperature of about 145 ° C. In Japan, this fiber is labeled Niplon, in America it is called Nylon 66.

The fabric is widely used for the manufacture of knitwear and shirts. They are also made from anida fur and sewing threads. The material is in demand, with each year the sales of the anide grow.

Nylon

Nylon is the first synthetic fabric based on polyamide, which appeared in the United States in the early thirties of the last century. Nylon glorified synthetic fabrics. The material became incredibly popular in the fifties of the last century.Women's underwear was inexpensive, it was socks, light, durable and pleasant to the touch. Men's shirts and jackets also looked presentable and favorably emphasized the figure. Nylon is widespread in Russia, called "synthetics".

Nylon is made from carbon with the addition of alcohol and water. It is labeled "6.6". Externally, nylon looks like silk.

Matter has the following properties:

- does not tear, withstanding large mechanical loads;

- does not fade when washing or exposure to ultraviolet radiation;

- does not absorb dust and dirt;

- the fabric does not deform over time;

- dries quickly.

However, nylon badly lets air, why often there are allergic reactions. as well as in production, the fabric is treated with toxic substances, which practically do not evaporate from the surface of products over a long time.

In our time, fashionable combination of artificial and natural materials. Polyamide fibers are present in men's and women's clothing, their number reaches, as a rule, one third of the composition. Nylon is added to silk and linen, making them more durable and elastic. Women almost immediately adopted this material, made of nylon:

- stockings;

- dresses;

- bras;

- blouses.

Nylon learned to reinforce, which made it possible to create practical outerwear. Cordura (a type of nylon) with the help of reinforcement are made backpacks and bags. Nylon is used for excellent textiles for housing:

- curtains;

- curtains;

- upholstery.

Their only flaw: they accumulate static electricity, which is a magnet for fine dust. It is recommended to wash nylon at a temperature of not more than + 32 ° C. Products can withstand a large number of washes. Upholstery is done with the addition of nylon up to 35%, the material received the name flock. In addition to nylon, it also has polyester.

Taslan

Taslan is denser than nylon, has increased strength, and taslan clothing “breathes”. The structure of the weave of the fibers of the rep using modern impregnations. Especially often used material for children's clothing:

- jackets;

- sporting goods;

- tourist equipment.

Puffs and winter jackets are made of good taslana. Inside, the taslan is covered with special impregnations that ensure reliable air exchange, at the same time the fabric reliably holds heat. The ease of the taslan beats all records: 1 m2, weighs only 182 g. The rep weave of the fibers forms a special scar that easily distinguishes the taslan from other materials. Outerwear is sewn from taslan nylon. Its peculiarity lies in the fact that different fibers are used, having their own labeling.

- 186T - lightweight material from thin threads.

- 310T - the material of their rather thick threads. A coat is made of it. Threads can be interwoven in parallel and form squares. If the label contains the words Rip-Stop or R / S, this means that the fabric has additives - additional fibers.

Taslan is also differentiated by tissue impregnation.

- Milky is a special whitish layer that is applied to the inside. The task of coating: to keep insulation inside the product and protect it from high humidity. Impregnation can be completely transparent.

- PU is the polyurethane layer designation. It feels like leather to the touch. Marking of PU 3100 indicates that the fabric has improved water resistance.

- WR - this marking indicates the presence of a layer that causes moisture drops to roll off the material without penetrating inside.

Jordan

Jordan (Jordan, Jonardan) - innovative fabric of the XXI century, which shimmers under the influence of light. Microweave of synthetic fibers are covered with a special layer of polyurethane, which adds strength. The material is lightweight and has excellent waterproof properties. The fabric effectively protects against moisture and at the same time ensures reliable air exchange. Jordan PU Milky WR is especially in demand.Such material has a well-dyed surface with anti-pilling texture. Impregnation of PU and BO gives the material additional functionality. The density of Jordan - 222 g / m2. The fabric does not let even a very strong cold wind, so it is made from it:

- tents;

- overalls;

- jackets;

- tracksuits for climbers.

Clothes can be washed many times, it does not lose its qualities.

Its advantages:

- soft and light;

- protects well;

- serves for a long time;

- pleasant to the touch;

- dries quickly.

Velsoft

Wellsoft (WellSoft) - this is another synthetic fabric, which has received wide distribution. The second name of the material - torn mahr. The material has a nap, located on two sides of the fabric, it is based on polyester. The fabric is created from ultrathin fibers with a thickness of 0.07 mm (100 times thinner than a hair). One thread contains up to 24 fibers. Due to this unique structure, the fabric has a high coefficient of strength and low weight. The fabric is treated with special chemicals, which gives it strength and softness. Wellsoft is very functional:

- dries quickly;

- does not pass cold air;

- practically not wrinkled.

There are several varieties, the fabric varies by criteria:

- the presence of a picture;

- coloration;

- thread structure.

Wellsoft can be called one of the best terry fabrics, which is ideal for sewing different clothes. The lack of material is that it does not have very good air exchange. Especially good from "Velsoft" plaids, bathrobes, children's costumes. Pile of fabric is resistant to the effects of temperature and humidity levels. Over time, the pile is not wiped, it keeps the length. Ironing such fabric is optional. She does not fade.

Tactel

Tactel has a complex double structure and has a lot of positive qualities. Perfectly passes air (one of the best materials on this indicator). Tactel is actively used in light industry, in particular, in the production of stockings and socks. Tactel was invented by the largest chemical corporation, DuPont (DuPont, USA) in 1983. Translated from the Latin language as "touch".

The fabric is made from a special artificial fiber based on Polyamide-6.6. Fibers are distinguished by extraordinary subtlety: just 7.9 microns, there can be about fifty such fibers per strand. The number of fibers is directly proportional to the softness and strength of the fabric. Thicker threads are on the inside of the fabric, thinner on the outside. Nowadays there are several dozen fabrics under the brand Tactel®. Mainly made from the fabric of the upper items and clothing.

Fabric can be:

- matte;

- sparkling;

- textured;

- iridescent.

Tactel is light and durable. Provides good air exchange and keeps warm well. Among the shortcomings can be called a high price.

Tactel-micro is used in the production of knitwear. Tactel® — textural incorporates heavy thick threads, fabric dense and elastic at the same time. Ideal for tailoring sportswear. Tactel® Diablo refracts the rays of light, causing the material to glow and sparkle. Usually from "Diablo" make lingerie. Tactel-aquator has two layers. The first consists of polyamide, the second layer is cotton. At high humidity, synthetic fabric removes excess moisture. Especially often Tactel-aquator is used in sportswear. Tactel Strata has a different thickness of thread, they are painted in different semitones, which is why the thing becomes iridescent color. Often "Tactel" is added to various fabrics:

- wool;

- cotton;

- mohair.

The material was widely distributed on all continents, in the press it was called “Cotton of the XXI century”.

Where do they apply?

It is important to note that polyamides are not susceptible to deformation and do not change their performance characteristics during the entire service life, therefore the material from them has found the widest application in many industries, as well as construction. Most often, polyamides can be found. Artificial materials are made of polyamides:

- capron;

- nylon;

- carpet

Many everyday things are made of polyamide:

- stockings and socks;

- tights;

- faux fur;

- items of children's clothing.

With the use of this material is made:

- technical fabrics;

- ropes;

- technical shoes;

- conveyor belts.

This material does not come into contact with food, therefore in the food industry polyamide is actively used to create:

- food containers;

- tanks for liquids;

- containers for packing cheese and dairy products.

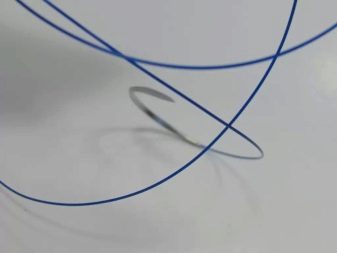

In medicine, it can be found in such products:

- implants;

- prostheses;

- surgical threads.

Care

Products made of synthetic fabrics are amenable to both hand and machine washable. The optimum temperature is not higher than 42 ° C. Synthetic things can also be ironed only if the temperature of the iron does not exceed 95 °.

Synthetic fabrics are afraid of chlorine compounds in any form, therefore, it is possible to remove stains without the use of any solvents.

How to produce synthetic thread, see the following video.