Suede is one of the most popular materials and is widely used in light industry and furniture manufacturing. Due to the high performance and attractive appearance of suede products do not lose their popularity over the years.

What it is?

Since ancient times, dressing hides of domestic and wild animals has been considered one of the main crafts of the peoples of the North. Starting from the Middle Ages, masters soaked deer skins with special compositions and animal fats, after which they sewed clothes and shoes from them. The processing technology of the skins in a somewhat modified form has reached our days, and the material obtained as a result of dressing has been called suede. Today, the impregnation of the skins is carried out on modern equipment using fish, seal and bone fat, as well as vegetable and ungulate oils. As a result of tanning, the skin acquires a thin and soft texture and becomes very durable and elastic. The material has a pleasant to the touch, fleecy on both sides of the surface, and is famous for its velvety and noble appearance.

Given the natural origin of raw materials, things made of natural suede are quite expensive. Therefore, thanks to modern technology, humanity has learned to produce material that perfectly imitates natural suede. Artificial canvas visually virtually indistinguishable from the prototype and are highly wear-resistant, resistant to stretching and abrasion, soft and pleasant to the touch surface and are much cheaper than natural material.

Varieties

Today there are two types of suede.

Natural

For the manufacture of suede used chamois, goat, antelope and sheep skin, and as the impregnating composition used seal fat or whale with the addition of vegetable, ungulate or linseed oil. After applying the solutions to the surface, fats and oils react with the skin fibers, oxidize and promote suede. To speed up the appearance of hairiness, the raw materials are presoaked in formaldehyde solution, and after fat processing they are placed in special machines, called impact grinders. In them, the material is subjected to continuous mechanical stress for 3-5 hours, after which it is settled in piles and warmed up. The process is repeated until the canvases become a yellow-brown shade.

Next, the material is thoroughly washed using a special solution, and then placed in a dryer. This is done in order to degrease the finished suede before being sent for painting. Freshly made natural suede has a non-uniform light brown color with the presence of light and dark spots, and therefore is subject to mandatory staining. At the end of a full cycle of treatment, suede ceases to pass water and acquires high water-repellent properties.

The advantages of natural suede include high strength, presentable appearance., excellent resistance to attrition and long service life of suede products. In addition, the material does not accumulate static electricity and does not pass water. Among the downsides, the cost and moral and ethical aspect are too high, due to modern trends in the use of environmentally friendly technologies and the rejection of the use of animal resources to meet human needs.

Artificial

Production of artificial suede is made in two ways. The first is to apply a polymer coating on the knitted base followed by laser grinding, which forms the pile. Cotton, wool and synthetic materials are used as the fabric base.The optimal ratio of artificial and natural fibers in the fabric is 25% cotton and 75% polyester.

To connect the fleecy part to the fabric substrate, a special PVA glue is used or a self-adhesive polymer is used. In some cases, lamination technology is used for bonding strength, after which it becomes impossible to separate the fleecy coating from the substrate. After the suede structure is formed, the material is subjected to Teflon treatment, as a result of which the fabric acquires high dirt-repellent and moisture-proof properties. If, as an experiment, a little water is poured onto the fabric, it will gather into large drops and, without being absorbed, will roll down from the surface of the material.

The second method of manufacture consists in fluffing microfiber with obtaining a soft and even fleecy surface. The pile formation process is carried out on a special brush equipment using microfiber fiber splitting technique to form small fibers. This suede is called woven and differs from the previous higher strength and resistance to deformation and stretching.

The advantages of artificial suede, which is sometimes called eco-suede, include high strength, durability, texture and color uniformity, unpretentious care and ability to ventilate. In addition, the material is pleasant to the touch and is not prone to the appearance of creases, the formation of cracks and abrasions. Among the minuses there is a special mark of white and gray products, the risk of damage to the fabric with the claws of domestic animals and low resistance to washing non-woven suede. For glued products with a fabric base, dry cleaning or processing with ammonia is recommended.

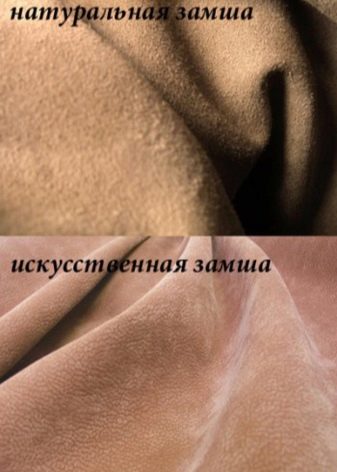

Differences from other materials

Before describing the differences of suede from textile fabrics and knitwear, it is necessary to understand what is the difference between artificial and natural materials. The main distinguishing feature of artificial suede is the absence of a nap on the second side, which, upon closer examination, makes it easy to distinguish it from natural. In addition, a layer of leather will be clearly visible on the cut of natural suede, while the fabric base is clearly visible on the artificial skin. The smell of materials is also different, and if the natural fabric has a persistent smell of leather, it is absent from artificial fabrics. You can distinguish the fabric and their texture. So, natural suede has a special softness and some non-uniformity of color even after dyeing, and artificial canvases are perfectly uniform and more rough to the touch.

If it is not possible to inspect the reverse side of the material and there are doubts about its naturalness, then it is recommended to hold the product in your hands for a while: artificial suede does not change its temperature and will remain cool, while the natural one will quickly heat up. In addition, if you hold your finger over the pile of natural material, the villi will change their position and the trail will become darker, while on the artificial canvas everything will remain unchanged. Another difference between natural and artificial material is the fact that when sewing clothes and footwear made of natural suede, the edges of the fabric are not processed, while the artificial webs need overlock. It is possible to distinguish materials by reaction to water. Natural suede instantly absorbs moisture and darkens, while water rolls down from artificial material, leaving no wet trace.

The main difference of suede from other types of synthetic and natural fabrics is universality. The material is equally suitable for clothing and footwear, which greatly expands the scope of its application and allows you to complement ensembles with leather goods and eye-catching accessories. Natural suede is often confused with nubuck.The main difference between these materials is the raw material for their production. For nubuck use the skin of larger animals, such as cows, moose and deer, and for suede use polishing technology using abrasive materials.

This process is called chrome treatment or tanning. In addition, the suede pile is much thicker and higher than that of the nubuck, and has a softer structure to the touch. Nubuck is often subjected to oiling, which enhances the waterproof qualities of the fabric, which, in turn, makes the material a little rough and coarse. The functional characteristics of nubuck are significantly lower than the working properties of suede. So, shoes made of nubuck, quickly get wet and dirty. And if suede shoes can be wet when cleaning, then only dry cleaning is allowed for nubuck.

Application options

Scope of natural and artificial suede is wide enough. The material is actively used for clothing and footwear, furniture upholstery, as well as for the manufacture of gloves, bags and jewelry.

clothing

Suede is used for sewing coats, jackets, jackets, skirts and coats. For the tailoring of outerwear, the ideal option is a jacket suede with a cotton or knitted base. Often, to enhance the decorative qualities of the fabric, nap is given a specific focus. Suede clothing fits nicely to the body, fits well on the figure and looks very decent. When buying a suede thing is better to choose products of light colors. This is due to the fact that on blue or black clothes small hairs, hairs and threads will be much more noticeable than on beige, sand or pink models.

When self-tailoring is better to choose an artificial fabric with a knitted base. Such suede, in contrast to the material with a base of cotton, is easier to sew and drape, making it well suited for sewing blouses and skirts. But for the manufacture of suits and jackets, on the contrary, it is better to buy just the cotton version. In addition, it should be borne in mind that when putting out details of thick suede on the material there are holes from needles and pins, and therefore the needles for sewing should be chosen as thin as possible and sharper.

Footwear

Suede shoes do not go out of fashion for many years. Due to its versatility and presentable appearance, shoes made of such material are perfectly combined with almost any wardrobe. In suede shoes or boots, legs always remain dry and do not freeze. The fabric successfully combines the ability to ventilate and repel moisture, because of what is often used for sewing sports shoes. For the production of such models used the skin of large animals, which has increased strength and durability.

Accessories and decorations

Suede leather goods are always at the peak of popularity. The material is ideal for sewing bags, gloves, straps and wallets, in addition to which you can always buy elegant jewelry in the form of a bracelet or pendant.

Furniture upholstery

For obtyagivaniya sofas and chairs in the furniture industry often use artificial suede, made of microfiber. This is due to the high performance of the material, such as abrasion resistance, the ability to retain the original color and ease of cleaning. In addition, the material is not prone to rolling and is available in a wide color palette.

Cleaning cloth

Thin perforated suede is widely used as a wipe and polishing material and is used to care for the surface of optical lenses, LCD monitors and plasma televisions. Suede cloth has a long life and does not lose its working qualities for a long time. In addition, the fabric perfectly absorbs water, does not leave behind whitish stains and dries quickly.This allows the use of material for washing car windows, headlights, interior and exterior.

Orthopedics

Due to the ability of the material to breathe, suede has found wide application in the manufacture of orthopedic insoles and specialized shoes. For these purposes, a special type of technical suede is used, the working qualities of which are clearly defined in the norms of GOST 3717-84. Sheep, goat and reindeer skins, characterized by a short nap and dark brown non-marking color, are commonly used as raw materials.

Technical objectives

In the manufacture of natural suede is often used pork split. Unlike cattle hides, it gives low-quality suede, which is used for sewing work gloves, aprons, casings for various equipment and technical equipment.

How to care?

Any suede is quite demanding in the care, so when you buy products from it, you need to consider some points. So, suede clothing made of microfiber and natural linen can be easily washed and even briefly soaked in warm soapy water, but the water temperature should not exceed 40 degrees. After washing, the product is recommended to slightly blot with an absorbent cloth and hang on the hanger. Suede clothing is strictly prohibited. In the process of drying, it is necessary from time to time to blot the cloth with a towel, otherwise numerous smudges may appear on the surface, which will be difficult to remove without repeated washing. Ironing a suede skirt or stretch coat is not necessary. The material is not prone to the appearance of wrinkles and bruises and perfectly restores the original shape.

In addition to washing, it is necessary to carry out regular dry cleaning of things. To do this, you can use a rubber brush, moving it in one direction of the pile. Freshly planted dirty spots in no case need to try to scrub. In such cases, you need to wait for complete drying of the stain, then shake off the dried dirt with an elastic brush and clean it with a silicone sponge. To remove greasy food stains, pour contaminated place with talcum powder and leave for three hours. Then gently shake off the powder with a brush and brush the product with a rubber brush. In the absence of talc, you can use starch diluted with ammonia to the consistency of gruel. In case of incomplete removal of the stain, mix water with ammonia in a ratio of 4: 1 and blot the stain.

It is necessary to hold the bristled after long storage, over the steam and comb it with a hard toothbrush. If the stains are fresh enough and have not yet had time to enter the material, then you can try to remove them with a cotton swab dipped in soapy water. To prepare the solution instead of soap, it is better to use shampoo, taken at the rate of 20 g per liter of water. After processing the stains with such a composition, it is necessary to collect the foam and quickly blot the area to be cleaned with a dry towel. Such cleaning should be carried out very quickly - so that the material does not have time to get wet.

Drying suede products is recommended away from heating devices and direct sunlight. Brown things are well cleaned with coffee grounds, and light and white - skim milk and soda, diluted in a ratio of 0.5 tbsp. l soda for half a glass of milk. Clothing colors are renewed using suede spray paint. The use of stain removers and acetone containing compounds is strictly prohibited. Uncomplicated stains can be removed with a regular soft eraser.

When caring for shoes and bags, you must use a sponge soaked in soapy water, while avoiding strong wetting of the product. After processing, the item is dried. and then combed with a hard brush. In winter, salt stains from reagents can be removed with 5% acetic solution.To do this, it is necessary to moisten a soft cloth in the solution and try to gently wash off the stains, paying more attention to the borders of the spot. However, many troubles can be avoided if the new suede shoes are treated with fluorocarbon or silicone water and dirt-repellent impregnation.

Care of furniture consists in regular washing of removable covers. As a rule, microfiber is used for their manufacture, so they are washed well. If the upholstery is not removed, then cleaning of stains and other contaminants is performed by any of the methods described above. The only prerequisite for cleaning a non-removable upholstery is to keep it as wet as possible, due to the risk of ingress of moisture and related difficulties. When buying furniture with suede upholstery, it is necessary to take into account that the height and density of the pile have a strong effect on abrasion resistance and the complexity of care. Thus, products with a short nap have better performance and are most preferable as upholstery for regular use. If the suede sofa has been around for quite a few years and it has begun to get greasy, then a special brush that has a combined design with the presence of metal and rubber elements or a regular eraser will help correct the situation. As for everyday care, such furniture should be regularly vacuumed, cleaned with dry salt and periodically combed with a soft brush.

Competent and timely care for suede products will allow things to retain their original appearance for a long time and not to lose their functional and decorative properties for a long time.

How to properly care for suede, see the next video.